sales@qlycheecrafts.com

Custom Wooden Coasters

Customization Process

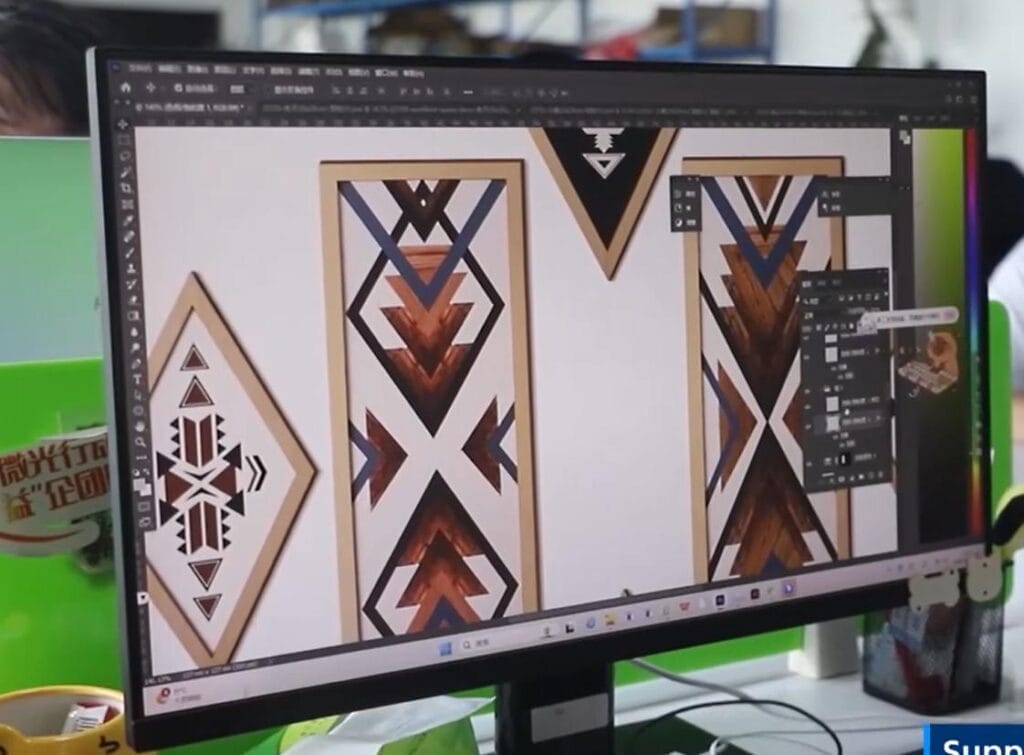

Concept & 2D Design

3D Modeling & Sample

Bulk Production

QA & Delivery

Certificate

Frequently Asked Questions

What customization methods do you provide for custom wood coasters and which suits each use?

We offer laser engraving, UV printing, screen printing, foil stamping and CNC/laser cutting. For durable brand marks in hospitality and bars, laser engraved coasters are ideal; for vibrant retail art or photo‑quality designs, choose custom printed wooden coasters; for metallic accents on gift sets, foil stamping works best.

Which wood species and formats are available for wooden coasters in bulk?

We supply olive, maple, walnut, birch, acacia and bamboo in round, square and natural tree‑slice formats. Solid blanks, laminated panels and reclaimed wood slices cover different price and aesthetic needs for wooden coaster set lines, retail assortments or promotional packs.

What finishes and non‑slip options ensure long life for wooden drink coasters?

Choose from food‑safe water‑based polyurethane, natural oil blends and satin or matte lacquers to protect against condensation and stains. We add cork, silicone or rubber backing to prevent slipping and surface damage—these features keep wooden cup coasters and wooden beer coasters performing in busy venues.

How can I use coasters with logo to improve marketing and sales?

Branded coasters function as micro‑advertising: place QR codes, promo codes or seasonal messages to drive web traffic and track engagement. Curated custom coaster sets and themed series (city maps, artist editions) increase retail appeal and encourage social shares, extending the life of each promotional touchpoint.

Do you support fulfillment services, samples and OEM packaging for promotional runs?

Yes — we provide sample approvals, OEM packaging, private‑labeling and dropship/fulfillment services for promotional coasters, custom wood drink coasters and wholesale orders. Ask for a sample kit to evaluate laser engraved coasters, printed proofs or blank wood coasters for local finishing before placing a larger order.

Do you offer customization options?

Yes, we provide customizable services that allow you to tailor products to meet your specific needs and branding.

What is your minimum order quantity?

We have changed the minimum order quantity to 100+ to make it easier for you to start with our products without the stress of large commitments.

Can you provide dropshipping services?

Yes, we offer dropshipping services, allowing you to deliver our products directly to your customers efficiently.

Do you provide bulk discounts?

Yes, we offer competitive pricing and discounts for bulk orders. Contact us to discuss your requirements.

How long does production take?

Typical production times range from 30 to 60 days after design approval, depending on the complexity and quantity of the order.

How We Turn Simple Wooden Coasters into Powerful Brand Tools — Featuring Custom Wood Coasters

We make and supply a wide range of wooden coasters that solve everyday operational needs while creating lasting brand impressions. From small boutique cafés to multinational hotel groups and promotional agencies, our products—designed, produced and quality‑checked by us—balance material choice, finishing, customization and packaging so you get coasters that look great, perform reliably and sell well. Below I explain how we approach every step: materials and feel, formats and SKU planning, decoration methods, use cases by industry, sourcing and fulfillment strategies, quality checks, sustainability options, merchandising concepts and practical ordering guidance. Along the way I reference common buyer searches so you can match product pages and procurement specs to real market demand.

Materials and tactile choices: match feel to function

We begin by helping you choose the right timber or composite for the intended use. Popular options include olive, maple, walnut, birch, acacia and bamboo—each species has different grain, density and finishing behavior that affects cost, engraving contrast and perceived value. For example, dark, dramatic grain in walnut or olive is ideal for premium hotel gifts and small‑run engraved wooden coasters, while maple and birch give a clean surface for high‑visibility laser engraved wood coasters used in cafés and corporate events.

We can supply solid wood blanks, laminated panels and natural tree slices. Solid pieces give a premium heft, but need proper moisture control to avoid warping; laminated products offer dimensional stability with less movement in humid environments. When customers ask for rustic or artisanal items, I recommend wood slice coasters bulk from carefully selected cuts—each piece has unique patterning and can become a signature product for wedding favors or local souvenir lines.

Common buyer requests include wooden coaster set configurations, single wood coaster SKUs, and mixed assortments. We size coasters typically between Ø90–110 mm for round pieces and 90×90–100×100 mm for square designs; thickness ranges from 3 mm (promotional blanks) up to 6–10 mm (premium retail sets).

Finishes and durability: protect surfaces, reduce complaints

A functional finish is critical. We use food‑safe coatings and waterproof surface treatments to prevent staining from condensation, alcohol and coffee oils. Standard finish choices we offer:

- Water‑based polyurethane for long‑term water and alcohol resistance; ideal for high‑turnover venues.

- Natural oil blends (food‑safe) to deepen grain and provide a warm hand‑feel.

- Matte or satin lacquers for modern aesthetics that minimize fingerprints.

- Clear shellac or high‑gloss coatings for retail gift sets where a polished look sells better.

We also fit non‑slip backing—cork, silicone dots or rubber discs—depending on use. Bars and restaurants often require robust non‑slip backing to avoid glass movement; for packaged retail we recommend thin cork pads to protect shelving and add perceived quality. These choices reduce maintenance and return rates for hospitality customers who order wooden drink coasters and wooden cup coasters in volume.

Shapes, formats and SKU planning: variety that scales

To serve different channels I design SKU libraries that balance choice and inventory efficiency. Typical form factors:

- Round coasters (Ø90–110 mm) — universal fit for mugs and glasses.

- Square coasters (90×90–100×100 mm) — easy to pack and display; searchers often use terms like square wooden coasters.

- Tree‑slice coasters — organic edges and one‑of‑a‑kind grain; excellent as personalized wooden coasters or wedding favors.

- Multi‑piece boxed sets — 4/6 piece retail sets in gift boxes or foam inserts for premium placement.

For wholesale and promotional buyers I recommend offering both finished custom wooden coasters and bulk blanks. Stocking blank wood coasters bulk lets local partners apply last‑minute branding—useful for event agencies and retailers. Mixed cartons (round + square + tree‑slice) let merchandisers test what resonates in different regions without heavy inventory risk.

Decoration and customization: choose the right method for the art and run size

Customization transforms coasters into marketing assets. We provide a spectrum of decoration options and advise on which method suits artwork complexity and batch size:

- Laser engraving: high‑contrast, durable marks suitable for logos, monograms and line art. Many buyers search for laser engraved coasters, laser etched coasters or laser engraved wooden coasters. Engraving penetrates the wood surface so the brand remains visible after heavy use.

- UV printing: full‑color, photographic prints for retail art and complex designs. Use when you need custom printed wooden coasters or promotional runs with colorful campaigns.

- Screen printing: cost‑effective for simple solid‑color logos across medium to large volumes.

- Foil stamping and hot foil: adds metallic accents that elevate custom coaster sets in gift markets.

- CNC / laser cut shapes: enable unique silhouettes and negative‑space logos—search terms include laser cut wooden coasters, laser cut coasters and custom laser cut coasters.

When you plan a campaign, I weigh artwork detail versus quantity. For long‑lasting brand exposure in hospitality, coasters with logo produced by laser engraving offer excellent durability. For retail impulse buys, UV printed customized coasters with vibrant imagery often convert better on shelf.

Use cases and buyer profiles: why different industries choose wood

Different buyers have different priorities; I work with each type to tune specs and packaging.

Restaurants & Bars

Operational durability rules. Venues buy wooden beer coasters and bar coasters that stand up to condensation, repeated clearing and wash cycles. Non‑slip backing and waterproof finishes are essential. We often recommend coasters logo engraving to promote house beers, cocktails or seasonal menus with minimal staff involvement.

Hotels & Resorts

Hotels want consistent guest experience. A branded coaster in the room or lobby bar—especially as part of a wooden coaster set or welcome pack—contributes to perceived quality. For loyalty or VIP programs I suggest personalized or limited‑run engraved coaster sets that guests can take as memorabilia.

Corporate & Promotional Buyers

Marketing teams look for items with long wear and low shipping cost. Promotional coasters and company logo coasters yield sustained impressions at trade shows and client events. We help design promo packs with QR codes or discount codes printed on the underside to measure campaign performance.

Retailers & Gift Makers

Retail sells variety and story. Personalized product lines—personalized coaster sets, personalized wooden coasters, personalized wood coasters bulk—do well in boutique stores and online. We assist retailers with seasonal assortments (holiday graphics, city maps, monograms) and premium packaging to justify higher price points.

Event & Wedding Planners

Customized wood slice coasters bulk and engraved keepsakes are popular as wedding favors and event table markers. We support small MOQs and fast sample approval cycles so planners can offer personalized items to clients.

Wholesale and distribution strategies: reduce risk, increase flexibility

For distributors and resellers I recommend a multi‑tier sourcing model:

- Stock core SKUs of finished wooden coasters in bulk to meet stable demand.

- Maintain a buffer of blank wooden coasters for local finishing (laser engraving or print) to enable faster delivery for bespoke requests.

- Offer private‑label packaging and OEM branding to help retailers present coasters as exclusive products.

- Provide sample kits (small paid order) to speed buyer approvals and reduce sampling delays.

This model helps balance inventory carrying cost with the agility needed for seasonal promotions and last‑minute event requests.

Quality control: the tests we run so you don’t have to

We apply a rigorous QC regimen across production to ensure every batch meets expectations:

- Material grading and moisture control: stabilize solid wood to minimize warping.

- Engraving proofing: test artwork on the chosen species to confirm contrast and legibility—important for wood coasters for engraving and engraved coasters.

- Finish abrasion tests: simulate repeated condensation to verify adhesion and color stability.

- Backing adhesion tests: stress test cork/silicone pads for long‑term performance.

- Dimensional checks: verify thickness and diameter tolerances for stacked packaging and retail display.

These checks reduce returns and complaints for high‑volume buyers such as restaurant chains and promotional agencies.

Sustainability and provenance: build trust with real claims

We can supply FSC or equivalent chain‑of‑custody certified timber and recommend low‑VOC, water‑based finishes to support corporate sustainability goals. For artisanal lines I propose reclaimed wood slices and eco‑friendly packaging—both attractive to consumers searching for personalised wooden coasters and eco‑conscious gifts. Transparent material sourcing and recyclable packaging help you win corporate and retail accounts that require credible sustainability documentation.

Packaging and retail presentation: elevate perceived value

Packaging transforms functional coasters into gifting items. Options I provide include kraft gift boxes with foam inserts, windowed tuck boxes, and eco‑friendly sleeves. For wholesale promo runs, minimal bulk cartons lower shipping costs; for retail, premium packaging enables higher shelf pricing. Offering OEM outer cartons and custom sleeves helps partners present custom coaster sets under their brand.

Pricing and margin levers: how to keep costs competitive while protecting margin

I work with clients to structure pricing that scales:

- Offer tiered unit pricing by volume and decoration complexity.

- Encourage set SKUs (4/6 pieces) and bundle combos (coaster + napkins) to increase average order value.

- Stock blank inventory for local finishing to lower logistics and duty costs.

- Provide sample kits at cost to expedite approvals and shorten sales cycles.

Fulfillment and logistics: methods that fit your channels

We support multiple fulfillment options: FOB, DDP, drop‑ship direct to stores or clients, and palletized shipments for large wholesale orders. For time‑sensitive campaigns, the blank‑stock/nearshore finishing model shortens lead times and reduces the risk of missing event deadlines.

Practical artwork and file requirements: speed approvals and avoid errors

To ensure smooth customization I specify file standards:

- Vector artwork (AI, EPS, SVG) for laser engraving and foil stamping.

- High‑resolution CMYK files for UV printing and screen printing.

- Clear color proofs and scaled mockups for approval.

- Consider engraving depth and negative space for thin fonts or fine details—some species char differently under laser, so we always recommend physical proofs.

Common search phrases and how I integrate them into product pages

When I write product pages and category content, I naturally include buyer terms so procurement teams and merchandisers find exact matches. Examples of the phrases I embed include custom wood coasters, custom wooden coasters, wooden coasters in bulk, wood coasters bulk, laser engraving coasters, coasters with logo, engraved coaster, personalized coaster set, wooden beer coasters, wooden drink coasters, wooden coaster set, custom printed wooden coasters, and many related long‑tail terms. I avoid keyword stacking and place keywords across headlines, body copy, feature bullets and technical specs so pages read naturally and rank for relevant queries.

Inspiration and merchandising concepts that sell

To help retail partners and marketers, I propose several tested concepts:

- Local landmark series: laser‑etched city maps or skyline art on personalized map wood coasters for tourist shops.

- Seasonal artist collaborations: limited runs with local illustrators on UV printed custom wood drink coasters.

- Corporate event kits: branded coaster sets with matching notepads and pens for conferences—use coasters with logo that double as keepsakes.

- Hospitality loyalty gifts: engraved coaster sets offered as tiered loyalty rewards for returning guests.

- DIY blank kits: sell unfinished wood coasters bulk with heat‑transfer or stamp kits for craft markets.

Ordering checklist: avoid common pitfalls

Before you place an order, confirm these items with your supplier:

- Exact wood species and sourcing claims.

- Size, shape and thickness tolerances.

- Finish type and food‑contact compliance if necessary.

- Customization method, artwork specs and proof process.

- MOQ per decoration method and sample policy.

- Packaging options and private‑label capabilities.

- Fulfillment terms: lead time, freight terms and drop‑ship services.

Case studies and results we’ve seen

When a craft brewery ordered branded coaster sets for a seasonal release, we recommended walnut rounds with laser engraving and silicone backing. The coasters became social‑media props, and the brewery reported higher on‑premise drink sales for the featured beer. A boutique hotel replaced generic paper coasters with boxed engraved coaster sets in rooms, and guest satisfaction scores improved for perceived room quality. A corporate client used printed coaster packs at a trade show to distribute discount QR codes; web traffic from the campaign increased measurably over baseline.

Technical notes and testing I recommend you require from suppliers

- Request sample proofs for every wood species to check engraving contrast.

- Ask for finish durability test results or perform a condensation soak test.

- Confirm backing adhesion warranty or expected lifetime under typical cleaning.

- If needed, request FSC/CoC documentation and details about finish materials (MSDS for low‑VOC claims).

Why work with us: our advantages

We combine sourcing expertise, in‑house customization capability and B2B fulfillment services so you get more than a single SKU supplier. Our advantages:

- Flexible MOQ and mixed‑SKU carton strategies to reduce your inventory risk.

- In‑house laser engraving, UV printing and CNC services for tight quality control.

- Packaging and OEM services that let you sell under your brand with minimal handling.

- Sample and proof workflows that accelerate approvals and reduce rework.

- Sustainability options and transparent material sourcing to meet corporate procurement requirements.

Final thoughts: small items, big impact

A well‑designed coaster program does more than protect tables: it becomes part of your brand story, a durable reminder of a guest’s experience, and a cost‑effective promotional channel. Whether you need custom wooden coasters for hotel amenities, wooden coasters in bulk for promotions, engraved wooden coasters for retail, or custom printed wooden coasters for a seasonal campaign, I can help you specify the right materials, decoration methods and packaging to meet your goals. Tell me your target use case, preferred species and decoration method—I’ll provide samples, mockups and a tailored quote so you can evaluate fit and margin.