sales@qlycheecrafts.com

Wooden Wine Boxes Wholesale

Crafted from sustainably sourced solid wood, these boxes offer durable protection and premium presentation for wine—ideal for wineries, retailers, and corporate gifting. Wooden Wine Boxes Wholesale are available in customizable sizes and finishes to fit single bottles, magnums, or mixed sets, helping buyers simplify SKUs.

Multiple closure options (sliding lids, hinged tops with magnets, rope handles) plus foam or fabric inserts ensure safe transport and elegant unboxing, reducing damage claims and returns. Logo engraving or full‑color printing enables clear brand differentiation and seasonal promotions.

Surface treatments include natural oil, clear lacquer, and food‑safe stains for moisture resistance in humid climates; export‑ready packing and stackable designs accelerate warehouse handling and lower shipping costs.

MOQ‑flexible OEM/ODM services, sample availability, and transparent lead times simplify procurement planning and margin forecasting for distributors and event suppliers.

Competitive bulk pricing, recyclable packaging, and consistent quality control deliver higher margins and stronger reorder rates. Contact Qlychee for samples, MOQ details, and tailored quotes.

Showing the single result

Customization Process

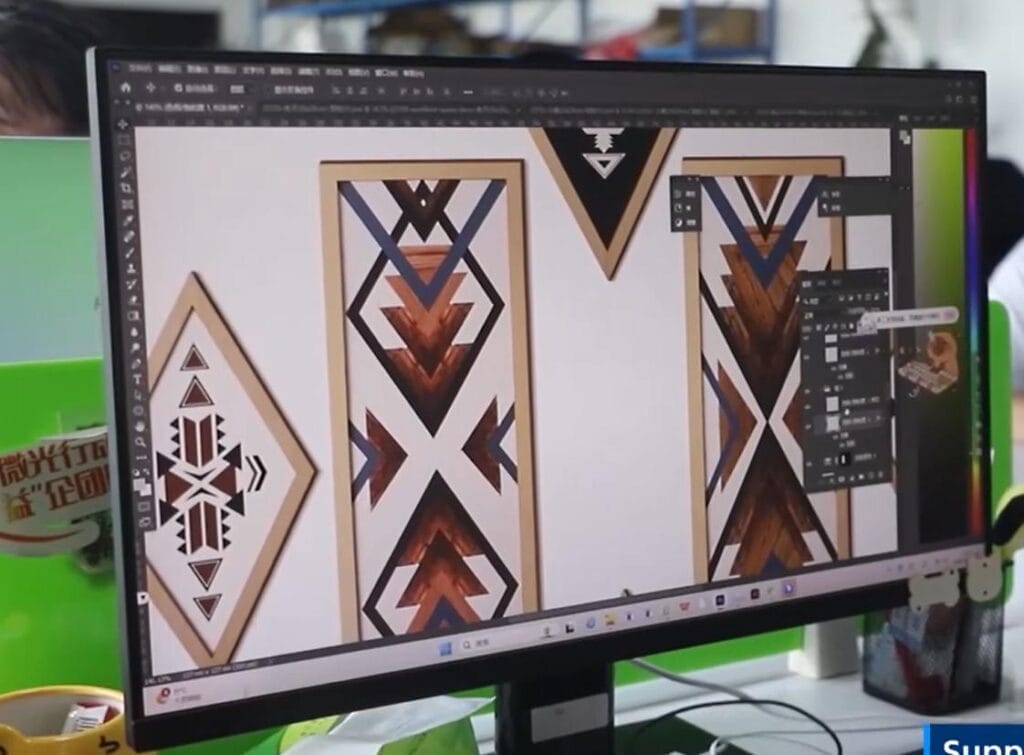

Concept & 2D Design

3D Modeling & Sample

Bulk Production

QA & Delivery

Certificate

Frequently Asked Questions

What wood species do you offer for wooden wine boxes and how do I choose?

We offer pine, poplar, beech, cherry, walnut and reclaimed wood. Choose pine for cost‑efficient runs and rustic looks; poplar/beech for smooth staining and mid‑range finishes; cherry/walnut for premium lines. Reclaimed wood provides unique textures for artisanal SKUs. When specifying a wooden wine box tell us desired finish, durability and target price so we can recommend the best species.

Can you produce custom sizes and inserts for non‑standard bottles?

Yes. We manufacture custom wooden wine boxes and custom wood wine box inserts (CNC foam, molded pulp, fabric lining, wooden separators). Provide exact bottle dimensions and handling conditions and we’ll propose cavity tolerances and protection options to minimize breakage.

Are your finishes food‑safe and suitable for gift packaging?

Yes — we use low‑VOC lacquers, food‑safe stains and approved adhesives on request. Specify if the box will contact consumables; we’ll provide technical data sheets to support compliance claims for wooden wine gift boxes wholesale.

Can you accommodate eco or reclaimed material requests?

Absolutely. We supply FSC‑sourced lumber, reclaimed wood options and recyclable molded pulp inserts. Buyers searching used wooden wine boxes wholesale or sustainable SKUs can get documentation on chain‑of‑custody and material origin.

Can you engrave individual names or order numbers for corporate gifting?

Yes. Variable laser engraving for personalised wooden wine boxes and custom engraved wood wine box programs is standard. We accept CSV order files and offer batching services to streamline fulfillment.

Do you offer customization options?

Yes, we provide customizable services that allow you to tailor products to meet your specific needs and branding.

What is your minimum order quantity?

We have changed the minimum order quantity to 100+ to make it easier for you to start with our products without the stress of large commitments.

Can you provide dropshipping services?

Yes, we offer dropshipping services, allowing you to deliver our products directly to your customers efficiently.

Do you provide bulk discounts?

Yes, we offer competitive pricing and discounts for bulk orders. Contact us to discuss your requirements.

How long does production take?

Typical production times range from 30 to 60 days after design approval, depending on the complexity and quantity of the order.

Wooden Wine Boxes Wholesale: A Practical Guide for Buyers, Brands, and Event Suppliers

I work with wineries, retailers, corporate gift teams, and event planners who need packaging that protects product, tells a story, and lifts perceived value. Over time I’ve developed an approach that balances craft, cost control, and operational ease — the same approach I use when sourcing a single premium crate or negotiating production runs of wooden wine boxes wholesale. In this guide I’ll cover design choices, materials, personalization options, logistics, sustainability, pricing strategies, quality control, and real-world use cases. I’ll also show how suppliers and buyers can collaborate to turn a simple wood wine box into a sales driver and a memorable customer moment.

Why wooden packaging still matters

When the goal is gifting, commemoration, or premium retailing, a plain carton will rarely do. A thoughtfully made wooden wine box communicates care, permanence, and value in a way that printed cardboard can’t. That translates into measurable benefits: higher average order value, longer on-shelf dwell time, social shares from delighted recipients, and, for corporate buyers, a more durable brand impression. Buyers searching terms such as wood wine box, wooden wine box manufacturer, or wooden wine box supplier are often evaluating packaging as a revenue tool rather than just a fulfillment expense.

Beyond appearance, wood provides structural protection. The right panel thickness, insert solution, and closure reduce movement and shock during transit. For brands that ship nationally or internationally, minimizing breakage is essential — which is why many clients shift from corrugated mailers to a fitted wood wine boxes solution for gift and limited-edition lines.

Who buys wooden wine boxes and what they need

Different customers approach packaging with different priorities. Understanding each use case helps me match the right product and service model.

- Wineries: They want presentation-grade boxes that reinforce brand narratives and protect premium bottles. Keywords they commonly use include custom wood wine box and engraved wooden wine box because engraving conveys quality and permanence.

- Retailers & Specialty Shops: Retailers need stackable displays, clear labeling options, and price-optimized SKUs. They search for wooden wine boxes bulk and wholesale wooden wine boxes to meet seasonal demand.

- Corporate gifting teams: Personalization is key. Terms like personalised wooden wine box and custom engraved wood wine box reflect the need for names, logos, and event-specific messaging.

- Event planners & hospitality: Speed of delivery, easy handling, and presentation count. They look for wooden wine gift boxes wholesale and bulk wooden wine boxes for conferences, weddings, and VIP experiences.

- Subscription services & DTC brands: They value protective inserts and fulfillment-friendly designs. Search terms include custom wooden wine boxes and custom wine boxes wooden to specify sizes and inserts.

By aligning feature sets to these buyer types, I help reduce unnecessary customization costs while maximizing commercial impact.

Material choices and how they affect cost and appeal

The wood species, panel thickness, joinery, and finish determine appearance, durability, and cost.

- Pine: Economical, light, and easy to finish. Pine is ideal for high-volume promotional runs and rustic designs. Many wholesale wood wine boxes use pine for cost efficiency.

- Poplar and beech: Mid-range cost with smoother finishes for staining and printing. These are common when brands want a cleaner look without the price of hardwoods.

- Cherry and walnut: Higher-end, with rich colors and a premium tactile feel. These are used for limited editions and high-margin corporate gifts.

- Reclaimed wood: Offers a unique aesthetic and strong sustainability story. Buyers searching used wooden wine boxes wholesale often want one-off textures and artisan appeal.

Construction choices matter too. Finger-joint or dovetail corners add strength and signal quality, while simple butt joints reduce cost. Sliding lids and hinged lids with magnets affect assembly time and perceived luxury; rope handles or cut handles change handling ergonomics and event suitability.

Inserts, protection, and presentation

Inserts are where protection and presentation meet. The choice usually depends on budget, required shock protection, and the unboxing experience.

- Foam inserts: CNC-cut foam gives perfect fit and excellent shock absorption. Ideal for rare vintages or fragile bottles. Buyers searching for custom wood wine boxes often specify foam for high-value shipments.

- Molded pulp: A recyclable, lower-cost option suitable for many bulk shipments. It offers moderate protection and aligns with sustainability goals.

- Fabric or velvet lining: Excellent for gifting and shelf presentation, though less protective during rough transport.

- Wooden separators or cradles: Good for multi-bottle boxes and crate-style displays.

I always recommend sample testing inserts with real shipment conditions. A box that looks great on a shelf but fails a simulated courier test will cost more in returns and reputation than the savings from a cheaper insert.

Personalization: engraving, printing, and modular branding

Personalization creates differentiation and premium margin opportunities.

- Laser engraving: High-detail, permanent branding suitable for names, logos, and custom messages. Keywords like laser engraved wooden wine boxes and engraved wooden wine boxes reflect buyer interest in this capability. Engraving is cost-effective for small runs because it requires minimal setup.

- Full-color printing: Offers striking visuals but requires attention to adhesion and surface prep on wood. Printed sleeves are a flexible alternative: you can change seasonal artwork while keeping the base box constant.

- Metal plaques, inlays, and embossing: These are premium touches used by brands that position bottles as collectible or commemorative items.

- Variable data personalization: Names, dates, and order numbers can be laser-engraved on demand, enabling DTC campaigns and corporate personalization without large MOQ penalties.

Combining scalable base SKUs with on-demand personalization is a strategy I use frequently: a standard box inventory plus localized engraving batches meets tight timelines and reduces SKU proliferation.

Sizing strategy and SKU rationalization

Too many SKUs complicate inventory and increase warehousing costs. I often advise clients to rationalize sizes around common bottle types: standard 750ml, magnum, and mixed set. Search phrases like custom wooden wine boxes and wooden wine boxes bulk indicate buyers want flexibility without complexity.

SKU consolidation reduces set-up fees and eases ordering. For example, offering three base box sizes (single, two-bottle, magnum) with modular inserts and sleeves covers most go-to-market needs. This approach balances customization with operational efficiency for buyers looking for wooden wine box wholesale pricing.

Fulfillment and logistics considerations

A packaging decision isn’t complete without thinking about how boxes will be packed, stored, and shipped.

- Stackability: Stackable designs improve palletization and reduce freight cost per unit. For distributors searching wooden wine boxes wholesale, this is a top priority.

- Pack-out density: How many boxes per carton, how many cartons per pallet, and total pallet height influence freight quotes. I request these specs early in supplier discussions.

- Assembly time: Flat-pack or easy-assemble designs save warehouse labor. Suppliers who offer kits (box + insert + closure) help fulfillment centers reduce pack time and error.

- Carrier compatibility: Choose box dimensions that meet carrier dimensional weight thresholds to avoid surprise charges.

I always run cost models comparing product cost, freight, and damage rates to find the true landed cost — not just the unit price.

Sustainability claims that matter

Sustainability is a buyer decision factor, not just a marketing line. Buyers often search for personalised wooden wine box or custom wooden wine box options that also highlight eco credentials. Useful claims include:

- FSC-certified wood or verified sustainable sourcing.

- Recyclable or compostable inserts (molded pulp).

- Reclaimed wood options for artisan lines.

- Low-VOC stains and food-safe finishes.

Verify claims with documentation: certifications, chain-of-custody info, or lab reports. Consumers and B2B buyers increasingly expect proof, and procurement teams will ask for it during RFPs.

Compliance and safety

Wood packaging that contacts food or is used in event catering must meet relevant safety and contact-surface guidelines. If you plan to ship internationally, understand phytosanitary regulations and ISPM-15 for wooden packing materials. Buyers searching for wooden wine box supplier or wooden wine box manufacturers should request technical sheets covering adhesives, finishes, and any certifications.

MOQ, pricing, and negotiation levers

MOQ is often the main friction point for smaller brands. Many suppliers offer tiered pricing: lower per-unit cost at higher volumes, with samples or pilot runs offered at modest MOQs. Common negotiation levers:

- Consolidate SKUs to raise total order volume.

- Commit to seasonal reorder schedules to secure capacity.

- Accept standard finishes instead of bespoke stains.

- Pre-pay or extend lead time in exchange for price concessions.

When buyers look for wholesale wood wine box or wooden wine box wholesale, they’re typically comparing these trade-offs. I recommend requesting a price grid that shows per-unit breaks at multiple quantity tiers so procurement can model scenarios.

Quality control and supplier selection

Quality control prevents costly surprises. I look for suppliers that provide:

- Pre-production samples and tooling approval.

- In-line inspection photos during production.

- Final inspection reports and random batch testing.

- Clear defect acceptance criteria and remediation plans.

Ask suppliers for references and past client work that matches your target aesthetics and functional needs. Suppliers advertising as wooden wine box manufacturer or wooden wine box supplier should be able to share case studies and lead times for similar orders.

Creative merchandising and event use

Wooden boxes are versatile display elements. For retailers and event organizers, they become props: stacked crates at tasting events, branded displays in stores, or VIP gift presentations at galas. I advise preparing merchandising kits with visual mockups, shelf layouts, and assembly instructions that show how wood wine boxes will perform in real environments.

Consider multi-use designs that convert from shipping pack to in-store display with a simple rearrangement — this reduces waste and increases perceived value.

Real-life examples and outcomes

I’ve seen several projects where careful packaging choices led to clear commercial outcomes:

- A boutique vineyard moved to a branded single-bottle wooden wine box with laser engraving and saw a measurable increase in average order value during holiday promotions.

- A subscription wine service standardized on a single wood wine box size and optimized inserts for quick fulfillment. The simplified SKU set reduced packing time and lowered weekly fulfillment errors.

- An events company leveraged personalised wooden wine gift boxes for wedding favor campaigns, using laser engraving to add names and dates. The personalization uplift justified premium pricing and repeat business.

These examples show that packaging decisions influence customer experience, operations, and revenue — not just the product’s appearance.

Common mistakes I help clients avoid

Experience teaches a few repeatable lessons:

- Ordering before sampling: Always test shipments to representative shipping lanes and seasons.

- Skipping insert testing: The wrong insert can cause breakage even if the box looks premium.

- Over-customizing small runs: Avoid expensive finishes for short campaigns; instead, use printed sleeves or limited-run plaques.

- Ignoring logistics: Large pallets that don’t stack efficiently create unexpected freight costs.

Addressing these early reduces delays and keeps campaigns on budget.

Trends I’m watching

Several trends shape how buyers approach wooden wine packaging:

- On-demand personalization: Laser engraving and small-batch personalization are becoming normalized for corporate gifting and DTC campaigns.

- Hybrid packaging: Combining a premium wooden box with a disposable outer shipper balances presentation and carrier handling.

- Reclaimed and artisan finishes: Consumers value a handcrafted look; reclaimed wood provides unique textures that support premium pricing.

- Modular systems: Base boxes that accept interchangeable sleeves or inserts reduce SKU count and support seasonal campaigns.

Understanding these trends lets buyers plan for both immediate needs and future flexibility.

How to structure an effective RFP for wooden wine boxes

When you’re ready to source, a clear RFP accelerates evaluation. Include:

- Target volumes and desired MOQ tiers.

- Exact bottle dimensions and any special shapes.

- Desired insert type and protection level.

- Branding files and personalization requirements.

- Required certifications (e.g., FSC, low-VOC finishes).

- Packaging and palletization requirements.

- Expected lead times and sample requirements.

An organized RFP helps suppliers quote accurately and speeds time-to-market.

Choosing between single sourcing and multiple suppliers

Single-source relationships simplify communication and QC but increase dependency. Multiple suppliers diversify risk and can reduce lead times regionally. For national rollouts I often recommend a primary partner and a vetted secondary supplier to cover peak seasons or regional demand spikes. When searching for wooden wine box suppliers or wholesale wooden wine box options, evaluate both capacity and geographic reach.

Final checklist before you place an order

- Order samples with your final artwork and chosen inserts.

- Run protective tests simulating your carriers and routes.

- Confirm stackability and palletization specs.

- Verify lead times and seasonal capacity.

- Get written specs and acceptance criteria.

- Agree on QC and remediation terms for defects.

This checklist reduces surprises and keeps production aligned with commercial goals.

Why I partner with Qlychee

I work closely with Qlychee because they combine manufacturing scale with customization flexibility that suits both wholesale and bespoke programs. Qlychee supports laser engraving, full-color sleeves, a range of inserts, and sustainable material options. They run sample programs, provide pre-shipment QC, and offer tiered pricing for wooden wine boxes bulk purchases. Their transparent communication and production traceability reduce procurement friction and allow my clients to meet tight seasonal deadlines without sacrificing quality.

Next steps I recommend

If you’re evaluating packaging options, start with these steps:

- Define the primary use case (retail, DTC, corporate gifting, event).

- Choose 2–3 candidate box sizes and insert options.

- Request finished samples with your artwork and intended finishes.

- Run a small pilot shipment to validate protection and unboxing.

- Build a simple ROI model comparing current packaging costs, breakage rates, and projected uplifts in AOV or margin.

If you share bottle dimensions (e.g., 750ml standard, magnum, or mixed sets), desired personalization (engraving vs. printing), and estimated annual volume, I’ll prepare a tailored spec sheet and cost comparison from Qlychee that shows MOQs, lead times, and per-unit pricing tiers.

If you’d like I can now:

- Create a ready-to-send RFP template tailored to the specs you provide.

- Mock up three SKU concepts (single-bottle, two-bottle, magnum) with recommended inserts and sample pricing tiers.

- Draft label and artwork guidelines for laser engraving and printed sleeves.

Tell me your preferred bottle formats, desired personalization level, and estimated annual volume, and I’ll get started.