What’s MDF wood? MDF, or Medium-Density Fiberboard, is an engineered wood product that’s become a staple in woodworking and construction. This complete guide will explore what MDF is, its key features, and how it compares to natural wood and plywood.

Key Takeaways

- MDF (Medium-Density Fiberboard) is made from wood fibers, resin, and wax, producing a smooth, knot-free surface.

- It is easy to paint and veneer, has uniform density, and works well for detailed designs.

- MDF is more affordable than solid wood and plywood. But it has poor moisture resistance, making it unsuitable for damp areas.

- MDF is ideal for indoor furniture, decoration, and crafts. It offers good design flexibility and cost-effectiveness.

- Choosing between MDF, plywood, and solid wood depends on the project’s requirements, budget, and environment.

Understanding MDF

What’s MDF Wood?

Medium-density fiberboard, commonly known as MDF, is an engineered wood product made from wood fibers mixed with resin and compressed to create a dense sheet.

The manufacturing process often involves breaking down hardwoods or softwoods into wood fibre, combining it with wax and a resin binder, and then applying high temperature and pressure. This results in a stable, uniform material without the knots or wood grain found in solid wood.

As a composite material, the surface of MDF is smooth and ideal for painting, applying laminates, or wood veneers. MDF is more affordable than solid wood, making it a popular material for many applications.

Key Features of MDF

MDF boasts several key features that distinguish it as an engineered wood product. Its smooth surface is perfect for achieving a flawless finish, as it is easy to paint.

Unlike natural wood, MDF lacks knots or a prominent wood grain, which enables consistent results when applying decorative veneers. The uniform density of medium density fiberboard ensures that it is easy to work with, making it suitable for intricate designs.

While MDF offers good durability for indoor applications, it is important to note the differences between MDF, plywood and real wood, especially concerning moisture resistance. MDF is generally not recommended for use in damp environments, as it can warp.

Types of MDF

There are various types of MDF, each engineered for specific applications.

- Standard MDF is the most common type, widely used for furniture, cabinets, and shelving.

- Ultralight MDF is another variant, offering a lighter weight while maintaining the characteristic smooth surface.

- Veneered MDF features a thin layer of real wood veneer on the MDF panel. It combines the aesthetic appeal of real wood with the stability and cost-effectiveness of MDF.

- Moisture-resistant MDF is treated to withstand higher humidity levels. It is suitable for kitchens and bathrooms (but not waterproof).

- Fire-retardant MDF is designed to slow the spread of flames.

Manufacturing Process of MDF Board

Raw Materials Used

The manufacturing process of an MDF board starts with the careful selection of raw materials. Typically, MDF is made from recycled wood fiber, often sourced from softwood trees such as pine or fir. These wood fibres can also come from sawmill waste or recycled wood scraps.

The fibers are then mixed with a resin binder, usually a urea-formaldehyde resin, and wax to improve moisture resistance.

The quality of the raw materials directly impacts the durability and overall quality of the MDF panel, influencing its strength and suitability for various applications.

Production Steps

The production of medium-density fiberboard involves several key steps.

First, the wood fiber is refined into a consistent, uniform material. This wood fibre is then dried and mixed with resin and wax. The mixture is formed into a mat, which is then pressed between heated plates under high pressure. This process bonds the wood fibres together, creating a dense, stable sheet.

The resulting MDF sheet is then cooled, trimmed to the desired size, and sanded to achieve a smooth surface. This meticulous process ensures that MDF maintains consistent thickness and density.

Quality Control in MDF Production

Quality control is a critical aspect of MDF production to ensure consistency and durability. Throughout the manufacturing process, the wood fibers are tested for moisture content and consistency. The resin mixture is carefully monitored to ensure proper bonding. The pressed MDF sheets undergo rigorous testing for density, strength, and dimensional stability.

Regular inspections are carried out to identify any defects, such as voids or inconsistencies in the smooth surface. Only MDF that meets the set standards for quality is approved for distribution, maintaining the reputation of MDF as a reliable engineered wood product.

Different Uses for MDF

Applications in Wooden Crafts

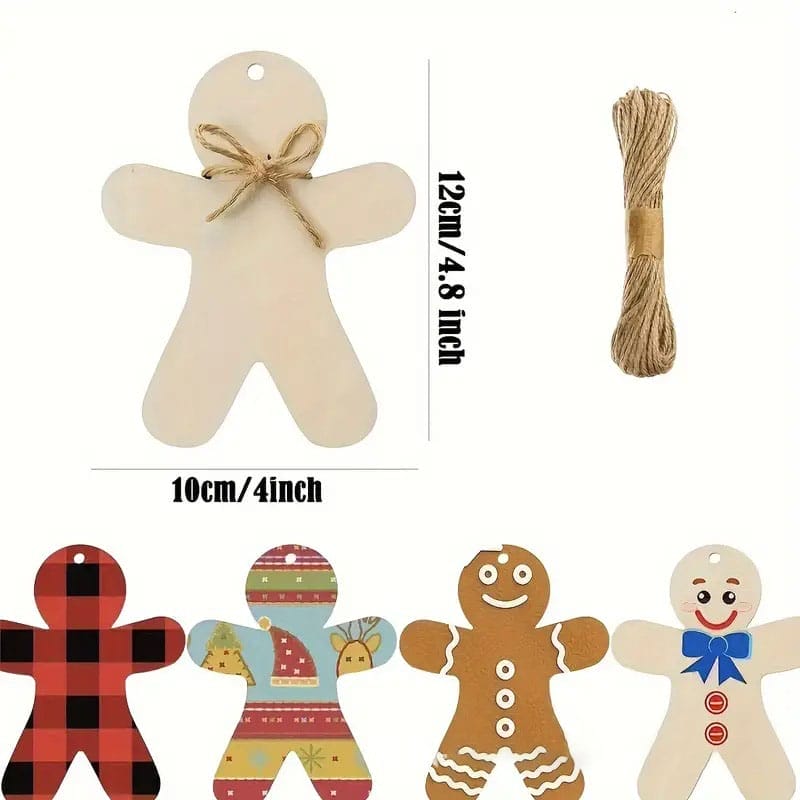

MDF is often used in a wide range of wooden crafts due to its smooth texture and uniformity. MDF provides an ideal surface for painting and applying decorative veneers. As an engineered wood product, medium-density fiberboard allows for clean cuts and intricate designs without the risk of splintering.

Crafters often use this material for making furniture, ornaments, and decorative panels. The absence of wood grain makes it easier to paint MDF to achieve a smooth finish. It is a popular material among hobbyists and professionals alike.

Wholesale and Customization Potential

The affordability and workability of MDF enhance its potential for wholesale and customization. Businesses can leverage MDF to produce large quantities of products at a lower cost compared to solid wood. The consistent density of medium-density fiberboard ensures that each piece meets the required specifications.

Customization is also streamlined as MDF’s uniform surface is receptive to various finishes and treatments. Whether for personalized furniture or mass-produced decorative items, MDF provides a reliable base for customization projects.

Advantages in Design Flexibility

MDF offers significant advantages in design flexibility because it is an engineered wood. The absence of knots and wood grain allows for greater creative freedom. Designers can easily create smooth, curved surfaces and intricate patterns with MDF that would be challenging to achieve with natural wood.

The ability to easily paint MDF and apply veneers also enhances its aesthetic versatility, enabling it to mimic the appearance of various types of wood. This medium-density fiberboard is easy to work with, making it a popular material.

Differences Between MDF, Plywood, and Real Wood

MDF vs Plywood

When comparing MDF and plywood, several key differences emerge. Plywood is an engineered wood composed of layers of wood veneer glued together, with alternating grain direction for strength.

MDF is made from wood fibers combined with resin and compressed. The choice between the two often depends on the application and desired finish. Some differences are summarized below:

| Characteristic | Plywood | MDF |

|---|---|---|

| Composition | Layers of wood veneer | Wood fibers and resin |

| Resistance to moisture and load | Better | Lower |

| Surface Finish | – | Smoother, easier to paint |

MDF vs Solid Wood

The distinction between MDF and solid wood lies in their composition and characteristics. Solid wood is a piece of wood harvested directly from trees, showcasing natural wood grain and knots.

MDF is an engineered wood product made from wood fibers and resin. It offers a uniform density and smooth surface. Here’s a comparison of their key attributes:

| Characteristic | Solid Wood | MDF |

|---|---|---|

| Material | Piece of wood | Engineered wood product made from wood fibers and resin |

| Other properties | Natural wood grain and knots. Provides superior strength and durability; it can be more expensive and prone to warping or cracking. | Uniform density and smooth surface. More affordable, stable, and easy to work with. |

MDF is a popular material for many applications, but it lacks the inherent beauty and structural integrity of natural wood.

Cost and Durability Comparisons

In terms of cost, MDF is generally more affordable than both plywood and solid wood. Its manufacturing process and use of recycled materials contribute to its lower price point. MDF is often used where cost is a significant factor.

Regarding durability, solid wood typically outperforms both MDF and plywood in high-stress applications and outdoor environments. Plywood offers moderate durability and better moisture resistance than MDF.

MDF is best suited for indoor use where it won’t be exposed to moisture or heavy loads. Understanding these trade-offs is crucial when selecting the right material for a project.

Final Words

In conclusion, MDF is a versatile and cost-effective engineered wood solution for various applications, including furniture, cabinetry, and decorative elements. Its smooth surface, uniform density, and ease of workability make it a popular material among woodworkers and designers.

While MDF may not possess the same strength or durability as solid wood, its affordability and design flexibility make it an attractive option for many projects. Understanding the differences between MDF, plywood, and real wood allows informed decisions to be made based on specific needs and priorities.

Ultimately, the choice between these materials depends on the intended use, budget, and desired aesthetic.

FAQs

What is MDF, and how is it made?

MDF (Medium-Density Fibreboard) is an engineered wood product made by compressing wood fibers mixed with resin and wax under high heat and pressure, resulting in a smooth, dense panel.

How does MDF compare to plywood and solid wood?

MDF has a smoother surface and is easier to paint. But it is less moisture-resistant and less strong than plywood or solid wood. Plywood offers better durability in humid conditions, while solid wood is the most durable but also the most expensive.

Can MDF be used in wet or outdoor environments?

Standard MDF is not recommended for damp or outdoor use as it can absorb moisture and warp. Moisture-resistant MDF can handle higher humidity but is still not fully waterproof.

What are common uses for MDF?

MDF is commonly used for indoor furniture, cabinetry, decorative panels, and crafts due to its smooth finish, affordability, and ease of customization.