When comparing laser cut wood vs CNC routing, we’ll find each has distinct advantages. Laser cutting excels at intricate details with kerf widths down to 0.1mm and clean edges for materials up to 1/4 inch thick. CNC routing handles thicker stock and achieves deeper cuts up to several inches.

We recommend laser cutting for precise, thin projects requiring minimal finishing. CNC routing is better for thick hardwoods and large-format pieces. Understanding their mechanical differences reveals which method best suits specific project requirements.

Key Takeaways

- Laser cutting excels at intricate designs with 0.1mm precision for thin materials, up to 12mm thick. CNC handles thicker wood materials effectively.

- Laser cutting produces cleaner edges requiring minimal finishing. CNC routing typically needs extensive sanding and post-processing.

- CNC routing offers deeper cuts and works better with solid hardwoods. Laser cutting is ideal for plywood and veneers.

- Laser cutting combines cutting and engraving capabilities with minimal waste. However, CNC offers greater versatility for large-format projects.

- Laser cutting offers faster setup and production for small batches. CNC routing excels in high-volume production once configured.

Quick Technical Overview

Let’s examine how laser cutting utilizes concentrated heat beams to achieve precise cuts as fine as 0.1mm, while producing clean edges that require minimal finishing.

CNC routing, in contrast, relies on high-speed rotating bits that cut through wood via friction. This enables deeper cuts and multidirectional capabilities for complex shapes.

Laser Cutting Basics

The laser cutting process employs concentrated beams of light to precisely cut and engrave materials through controlled thermal reactions.

We can achieve excellent cuts down to 0.1mm while minimizing material waste. The non-contact approach of the laser beam provides superior precision compared to CNC routing, especially for intricate designs.

When cutting wood, the laser’s heat seals the edges as it cuts. This eliminates the need for additional finishing work.

We utilize fume extraction systems to manage the smoke produced during the cutting process. This technology enables us to create detailed engravings and precise cuts with remarkable efficiency.

CNC (Computer Numerical Control) Routing Machine Basics

Unlike laser cutting’s thermal approach, CNC routing relies on mechanical material removal through high-speed rotating bits. We use cylindrical bits that enable multidirectional cutting, perfect for creating intricate designs in wood.

The adjustable cutting depth along the Z-axis allows for precision shaping of varied depths and profiles.

While CNC routing excels at complex woodworking tasks, we must consider its limitations. The setup process involves multiple steps to achieve quality results, which can impact operational efficiency.

Sharp corners present challenges due to bit radius constraints. Additionally, waste generation is higher compared to laser cutting, necessitating proper cleanup and disposal procedures.

Laser Cut Wood vs CNC: Precision and Detail Capability

We’ll examine how laser cutting achieves remarkable precision with kerf widths as small as 0.1mm. At the same time, CNC routers are constrained by their cutting bit radius for internal corners and fine details.

Feature Comparison

When comparing precision capabilities between laser cutting and CNC routing, notable differences emerge in their fundamental cutting characteristics. Let’s examine these key features:

| Feature | Laser Cutting | CNC Routing |

|---|---|---|

| Kerf | 0.1 mm | 0.5–3 mm |

| Min Cut Width | 0.1 mm | Limited by bit size |

| Internal Details | Sharp, precise | Limited by tool radius |

We’ll find that laser cutting excels in achieving finer details with its minimal kerf and superior minimum cut width. While CNC routers offer depth-cutting advantages, they can’t match laser’s precision for intricate internal details.

Laser cutting also offers dual functionality, combining profile cutting and engraving capabilities. This delivers cleaner edges that typically require no additional finishing.

Examples of Products Where Each Excels

Based on their distinct precision capabilities, laser cutters and CNC routers each demonstrate superior performance in specific product applications.

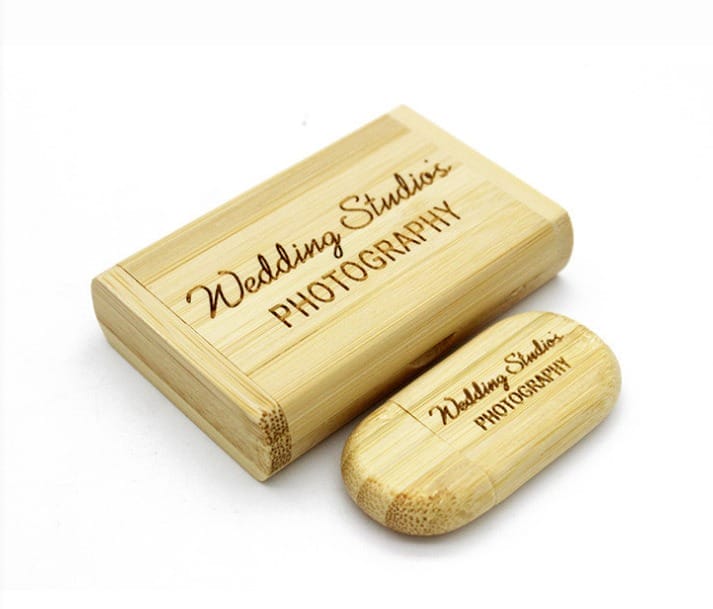

Laser cutting excels in creating intricate designs for jewelry, gift items, and detailed engravings requiring precision cuts down to 0.1mm. We see ideal results when cutting thin materials for flat-pack designs with clean, sealed edges.

CNC routers dominate in furniture production, handling thicker materials with deep cuts and efficient material removal. They’re particularly effective for carving out custom shapes in signage and large-format lettering.

While CNC machines excel at substantial projects, they can’t match lasers’ ability to produce ultra-fine internal details and sharp corners.

Laser Cut Wood vs CNC: Surface Finish and Edge Quality

Laser cutting creates distinctive charred edges and a heat-affected zone that many consider aesthetically pleasing. CNC routing often results in fiber tear-out that requires additional finishing.

Edge Char (Laser) vs Sanding/Tear-Out (CNC)

The distinctive edge characteristics of laser cutting and CNC routing create markedly different surface finishes in woodworking projects.

Laser cutting produces immaculate edges with a minimal heat-affected zone of 0.1mm. But CNC routers often leave rough surfaces requiring additional sanding.

The laser’s heat seals wood fibers, preventing fraying and creating an appealing burnt aesthetic that can enhance designs. In contrast, CNC routing’s mechanical forces can cause tear-out and exposed fibers.

When intricate details are essential, laser cutting’s precision eliminates the need for extensive post-processing. This makes it more efficient for achieving superior edge quality.

Post-Processing Needs and How That Affects Production Cost/Time

When evaluating production efficiency between laser cutting and CNC routing, post-processing requirements greatly impact both timeline and cost calculations.

Laser cutting delivers superior edge quality with minimal need for additional finishing work. It creates clean, precise cuts that maintain dimensional stability.

In contrast, CNC routers typically require extensive post-processing to achieve a comparable surface finish. This increases both labor costs and production time.

The elimination of sanding and finishing steps with laser cutting, combined with reduced material clamping requirements, creates a more streamlined workflow. This efficiency advantage becomes particularly evident when producing intricate designs that demand high precision.

Laser Cut Wood vs CNC: Material and Thickness Range

We’ll explore how laser cutters achieve ideal results with thin materials like plywood, MDF, and veneers up to 1/4 inch thick, while preserving intricate detail and minimizing waste.

For thicker stock and solid hardwoods exceeding 1/4 inch, CNC routers offer superior cutting capabilities and can effectively process substantial panels several inches thick.

When working with veneered or laminated boards, we must consider that lasers excel at precise surface detail but may burn edges, while CNCs can cleanly cut through multiple layers without scorching.

Best Wood Types for Lasers and Max Practical Thickness

Selecting the appropriate materials plays a crucial role in achieving ideal laser cutting results. Plywood, MDF, and veneers emerge as top choices due to their consistent performance and clean cutting characteristics.

When laser cutting wood types, plywood offers exceptional stability up to 12mm thickness. It’s perfect for intricate designs.

MDF’s uniform density allows precise cuts between 3mm and 15mm. Veneers excel in detailed work under 3mm thickness.

We’ve found that the practical maximum thickness for laser cutting tools typically ranges from 3mm to 12mm. This depends on the laser power and the type of wood used.

What CNC Handles Better

CNC routers excel at processing materials that surpass laser cutting’s capabilities, particularly in handling solid hardwoods and thick panels up to several inches in depth.

We find that the CNC machine’s robust metal cutting bits efficiently remove material from dense substrates. This makes it ideal for furniture-making projects requiring structural integrity.

The router machine’s depth adjustments along the Z-axis enable detailed work in thicker sections of wood panels, something lasers can’t match.

While CNC cutting generates more waste, it compensates by processing larger workpieces with substantial dimensions.

This versatility makes it the go-to choice for projects involving solid hardwoods that demand both precision and strength.

Considerations for Veneered or Laminated Boards

Material composition plays a critical role when processing veneered or laminated boards. The thicknesses range from 1/8″ to 3/4″, determining the best cutting method.

Laser cutting excels with thinner veneered boards, creating clean, sealed edges and intricate patterns without substrate damage.

For thicker laminated boards, we recommend CNC routers. This is due to their superior material handling and deeper cutting capabilities.

However, we must carefully control the cutting process to prevent damage to the surface layers from tear-out.

When using laser cutting, we need proper fume extraction systems for a safe working environment. These materials can release harmful emissions during processing.

Laser Cut Wood vs CNC: Production Speed and Scalability

When running production batches, laser cutting technology excels in high-volume efficiency. This is due to its superior nesting capabilities and minimal setup requirements.

CNC routing may prove more practical for specialized large-format pieces where material thickness exceeds laser capabilities.

Batch Runs: Which Method Is Faster Per Unit at Low vs High Volumes

Laser cutting excels in low-volume production. It achieves 10-100 inches per minute with minimal setup and delivers precision cuts that require little post-processing.

For high-volume production, CNC routers prove more efficient. It reaches speeds of 40-200 inches per minute once properly configured for batch runs.

Though CNC requires a longer initial setup, it’s more cost-effective for large volumes. Laser cutting’s quick setup and clean edges make it ideal for smaller batches.

Setup Time, Nesting Efficiency (Laser) vs Tool Change and Fixturing (CNC)

When comparing cutting services, laser cutting machines excel with minimal setup time and superior nesting efficiency. We’ll achieve tighter material utilization as lasers can pack designs closely without tool path concerns.

CNC routers require more extensive preparation, including tool changes and fixturing, which impacts production speed. For scaling operations, laser cutting’s batch production capabilities offer quicker turnaround, especially when handling repetitive tasks.

We can shift between projects more quickly without the additional labor of changing tools and securing materials.

CNC vs Laser Cut Wood: Sustainability and Waste

Sustainability has become a critical factor in modern manufacturing. So, the differences in waste production between laser cutting and CNC woodworking deserve careful examination.

We’ve found that laser cutting considerably reduces waste material compared to CNC woodcutting through precise, heat-based cuts that minimize offcuts. The sealed edges from laser engraving processing eliminate the need for additional finishing, further decreasing material waste.

Laser cutting’s precision and sealed edges minimize material waste. It’s a more sustainable choice than traditional CNC woodcutting methods.

While CNC routers require larger setups and generate more waste through physical material removal, laser cutting’s integrated fume extraction systems support eco-friendly practices.

This technology aligns with sustainable wood sources and optimizes material usage for environmentally conscious manufacturing.

When to Choose One, When to Combine Both

Selecting between laser cutting and CNC routing depends primarily on the specific requirements of your project and the characteristics of the material.

We’ll use laser cutting for intricate details and fine text, where precision down to 0.1mm matters. CNC routers excel with thicker materials and larger furniture pieces requiring complex shapes.

Consider a dual approach when projects demand varied capabilities.

We can maximize efficiency by combining the precision of laser cutting for detailed engraving with the robust material handling of CNC routing for deeper cuts. This strategy proves cost-effective: use lasers for small, detailed runs while deploying CNC routers for larger-scale production and substantial material processing.

Conclusion

We’ve examined how laser cutting and CNC machining each excel in distinct applications. While lasers offer superior precision for intricate designs and thin materials, CNC provides unmatched versatility for thick stock and 3D capabilities.

For best results, we recommend combining both technologies. Use lasers for detailed surface work and CNC for structural components. The choice ultimately depends on material specifications, production volume, and design complexity.

Browse our various collections of wooden crafts to discover unique pieces. For any customizations or bulk orders, contact us today for a personalized quote.

FAQs

Is CNC or Laser Cutter Better for Woodworking?

We’ll need CNC routers for deep wood cutting and furniture projects. But let’s choose laser cutters when we’re creating detailed patterns or need clean, sealed edges with minimal post-processing work.

What Are the Disadvantages of Laser Cutting Wood?

Laser cutting produces harmful smoke and can cause material warping. It often requires multiple passes for detailed work and struggles with thick materials. For large projects, it’s slower than CNC, reducing production efficiency.

Is Laser Cutting More Expensive Than CNC?

We’ll typically pay more initially for laser cutting equipment. But operating costs can be lower due to reduced material waste and faster production times compared to CNC’s ongoing tooling and maintenance expenses.

Can Laser CNC Cut Wood?

Yes, we can cut materials using laser CNC machines with high precision, achieving cuts as small as 0.1mm. We’ll get clean, sealed edges while minimizing wood expansion and enabling intricate designs.