sales@qlycheecrafts.com

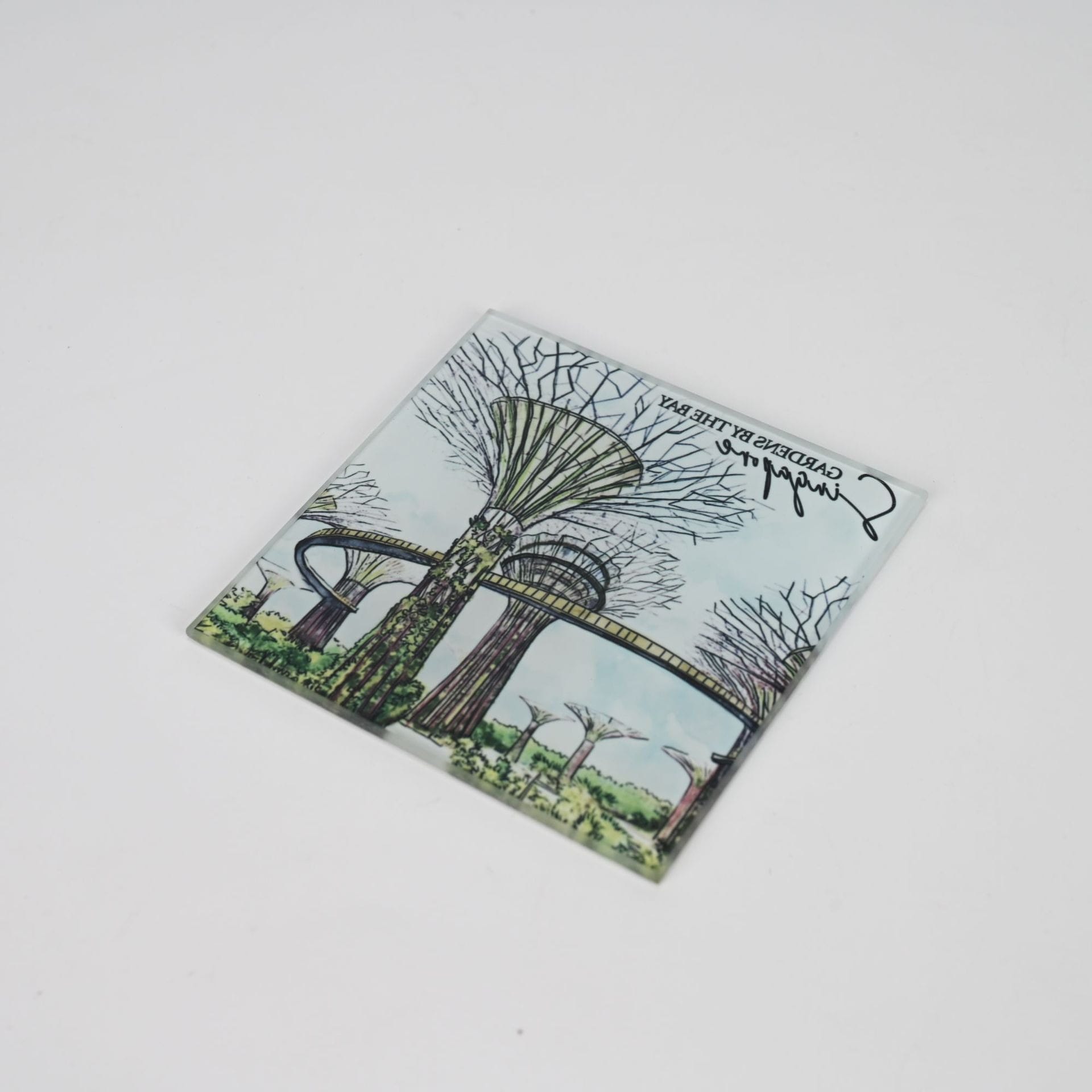

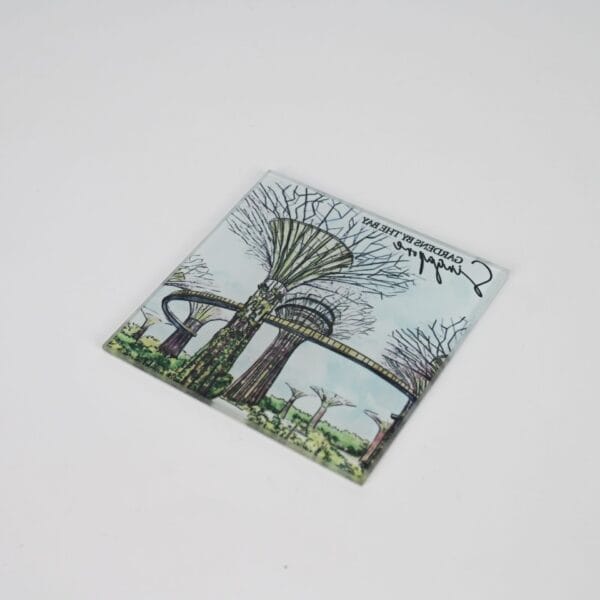

Custom Printed Wooden Coasters — 100×100mm Square with Cork Back

- Durable sublimation-ready surface for vivid, full-color prints — ideal for logos and photo designs. Boosts brand visibility with custom printed wooden coasters that keep prints sharp after repeated use.

- Multiple material & backing options: choose cork-backed MDF, pure cork, rubber, fabric, ceramic or stone variants to match service environments. Cork-backed versions prevent slipping and protect tabletops.

- Standard square sizes (90–100mm) fit most cups and glasses; consistent dimensions ensure efficient packing and retail display. Low deformation and stable flatness support bulk fulfillment and merchandising.

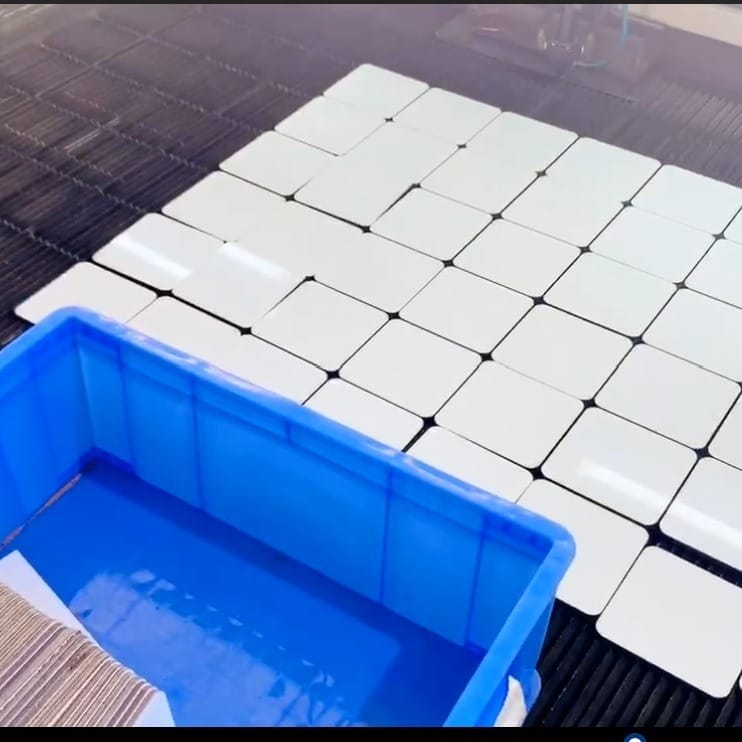

- Factory-friendly production: supports heat-sublimation and heat-transfer printing with low MOQ and fast repeat runs, enabling quick reorders for cafés, hotels, and merch sellers. Carton packing (480 pcs / 20 kg) optimizes shipping cost per unit.

- Easy quality control and low after-sales risk: clear inspection points for print adhesion, edge finish, and cork bonding reduce returns and maintenance. A practical, cost-effective promotional item with strong B2B ROI — custom printed wooden coasters ready for bulk supply.

- One-stop service from design to delivery

- Free design support for beginners

- Production progress tracking

- Custom laser cutting & printing

Product Name Custom Printed Wooden Coasters SKU 180445 Place of Origin China Zhejiang Material MDF, Wood, Customized Product Type Custom Wooden Coasters Technique Laser Engraving/Laser Cutting/UV Printing Theme Modern minimalist, Nordic-inspired, Rustic natural, Eco-friendly gift, Corporate branding, Café & hospitality warm décor, Promotional giveaway, Retail homewares, Sustainable kitchenware, Photographic prop Use Drink coaster, Cup and mug protection, Teapot mat, Tabletop surface protector, Corporate gift, Event giveaway, Café and restaurant tabletop accessory, Hotel room amenity, Retail boxed set, Promotional merchandise, Photo styling prop, Subscription box add-on, Office desk accessory, Home dining/tea service Packaging Method OPP bag/Carton Package(Custom Available) OEM/ODM Warmly Welcomed Mode of shipment By air or by sea or your request Logo Laser engraving, UV Customized Logo Size & Color 10*10*0.65cm, Customized Weight 110g Sample Available MOQ 100 Piece Shape Round/Square/Irregular/Customized Elevate Your Brand Experience with Customized Wooden Coasters

When I source promotional items or stock my café and retail outlets, I look for pieces that do more than just serve a function — they tell a story, protect surfaces, and become a repeat purchase driver. Square wooden coasters, especially those designed for printing, hit all those marks. They’re tactile, visually appealing, and versatile across hospitality, corporate gifting, and merchandising. Below I walk through why these coasters make sense for different buyers, how material and production choices affect their performance, and what practical considerations matter when ordering in bulk. Throughout, I reference how our product stands out and how you can match the right variant to your business needs.

Why choose printed wooden coasters for your business?

Subtle branding opportunities are everywhere in hospitality and retail. A coaster sits under every drink and becomes a small stage for your logo, message, or artwork. That’s why I recommend considering custom printed wooden coasters for cafes, bars, hotels, and merch stores: they combine a warm, premium feel with printing surfaces that accept vivid colors and crisp detail. Compared to disposable paper coasters, wooden and MDF bases feel longer-lasting and reinforce perceived value in the customer’s mind.

Who benefits most from these coasters?

- Cafés and coffee shops that want an affordable, durable branded touchpoint at table level.

- Bars and breweries needing slip-resistant bases that survive spills and frequent handling.

- Hotels and event planners seeking consistent, elegant coasters for meetings, rooms, and banquets.

- Merch sellers and e-commerce brands wanting low-cost, high-margin add-on products.

- Corporations ordering corporate gifts or conference giveaways with logoed items.

Material choices and why they matter

The product family includes several material and backing combinations — cork-backed MDF, pure cork, rubber, fabric, ceramic, and stone. Each choice serves a practical purpose.

Cork-backed MDF: This is the most balanced option for hospitality and merch. The MDF top accepts heat-sublimation and heat-transfer printing cleanly, yielding vivid, full-coverage graphics. The cork backing prevents slipping, protects tabletops, and dampens noise. In high-turnover environments like cafés, cork-backed MDF coasters are resilient, flat, and easy to stack for POS displays.

Pure cork: Cork coasters are naturally absorbent and eco-friendly in appearance. They’re great for casual venues and gift packs. Printing on pure cork can be more textured, which adds a handcrafted feel to the design; choose image styles that suit slightly organic print results.

Rubber-backed or rubber coasters: These provide the best non-slip performance and are ideal for bars and outdoor seating where condensation is frequent. Rubber bases also add durability if coasters are frequently stacked or slid across surfaces.

Fabric variants: Fabric-topped coasters are useful in settings emphasizing softness and décor — boutique hotels, wedding catering, and interior shops. The printed fabric surface can reproduce textile patterns and photographic imagery when treated for sublimation.

Ceramic and stone: These variants elevate the product into gift and souvenir territory. Ceramic and stone coasters are heavier, convey premium quality, and pair well with boxed sets. They’re suitable for retail where perceived value commands a higher price point.

Printing methods and surface considerations

For reproduction quality and consistency, heat-sublimation and heat-transfer printing are the top choices for these substrates. Sublimation yields bright, durable color on coated MDF and suitable fabrics, and works particularly well when you want photographic-grade images or gradients. Heat-transfer vinyl or direct-to-surface printing can also produce crisp logos and vector art on MDF and coated surfaces.

When I advise clients on artwork, I emphasize color contrast, bleed area, and simplified elements for superior legibility at coaster scale. Small type and intricate detail can get lost when replicated at 90–100mm square; bold logos, simplified icons, and strong color palettes perform best.

Size and shape: square advantages

Squares are efficient for packaging and display. The 90–100mm square size family fits most glassware and cup bases while maximizing printable area. From an operational perspective, square coasters pack tightly in cartons and display trays, lowering freight weight and wasted space. For retailers, square coasters align better in shelf displays and boxed gift sets, which improves visual merchandising and conversion.

Practical benefits for B2B buyers

Durability and maintenance: Properly manufactured wooden coasters with cork backing resist curling and maintain flatness under normal service conditions. Their resistance to moderate moisture and temperature fluctuations reduces replacement frequency, which lowers long-term procurement costs.

Cost-efficiency in bulk: These coasters typically ship in bulk cartons that optimize cost per unit. For businesses ordering thousands of units, the cartonized packaging and consistent sizing minimize handling time and shrink the overall landed cost.

Customizability and variety: Offering a range of materials and backing types means you can segment your SKUs: a core cork-backed MDF for daily service, ceramic for retail gift sets, and fabric or pure cork for special promotional runs. That SKU segmentation supports both everyday needs and seasonal upticks.

Cross-industry use cases

Cafés and coffee shops

I often recommend cafés use custom printed coasters wholesale as a low-cost way to reinforce in-store branding. Coasters are frequently swapped and taken, and having a distinctive design can encourage social sharing (customers post drinks with your coaster visible). They’re also simple upsell items at the register or part of gift bundles.

Bars and breweries

Bars benefit from the slip resistance and durability of rubber-backed or cork-backed coasters. For breweries, coasters also serve as collectible memorabilia when printed with seasonal designs. Ordering custom printed bar coasters in limited runs for seasonal releases or tap takeovers is a proven engagement tactic.

Hotels and event venues

Uniformity and elegance matter in hospitality. Coasters printed with hotel logos and contact details subtly extend brand presence into rooms and meeting spaces. Ceramic and stone options serve well in executive spaces and VIP gifting scenarios.

Merch sellers and e-commerce

For sellers on marketplaces or their own sites, coasters are lightweight, inexpensive to ship, and easy to bundle with mugs and candles. They often produce attractive margins and are compatible with drop-shipping arrangements. Including a set of themed custom printed drink coasters in a product bundle can lift average order value.

Corporate gifting and promotional events

Companies ordering for trade shows or conferences value the portability and brand visibility of coasters. Compared to higher-ticket items, coasters are cost-effective giveaways that remain on desks or in staff kitchens, creating ongoing impressions.

Design tips that drive conversion and retention

- Use high-contrast palettes so logos stand out on small surfaces.

- Favor bold, simple marks over intricate lock-ups to preserve legibility.

- Consider on-trend illustration styles for merch sellers—minimalist line art or muted, Scandinavian-inspired colorways often resonate.

- When printing photographic content, test on coated MDF or fabric to ensure color fidelity.

- For bar applications, prioritize rubber or cork backing for grip and longevity.

Packaging and logistics: what I care about as a buyer

Efficient packing is non-negotiable for bulk buyers. Cartons that hold 480pcs and weigh around 20kg are ideal for minimizing freight cost per unit. Well-organized inner packaging (sleeves, dividers, or small stacks with kraft separators) protects edges and printed surfaces during transport. For retailers and fulfillment centers, pallet-ready cartons and consistent carton dimensions simplify receiving and inventory workflows.

Lead times, MOQ, and reorder cadence

In my experience, suppliers offering low MOQs for prototyping followed by predictable lead times for reorder runs are the most valuable. Heat-sublimation and transfer processes are batch-friendly: once artwork and color profiles are locked, repeat orders can proceed with minimal variation. This makes it easy to keep core SKUs in rotation and test limited-edition prints without large upfront commitments.

Quality control checkpoints I always use

- Dimensional check: confirm 90–100mm square tolerance and uniform thickness.

- Print adhesion: rub tests and water exposure checks for sublimation or transfer prints.

- Edge finish: inspect for splinters, chipping, or uneven sealing.

- Backing bond: verify cork/rubber/glue adhesion across several random samples.

- Packaging integrity: random carton opening to confirm inner packing and protective materials.

Sustainability and perceived value

While not all variants are fully biodegradable, choices like cork and wood-based MDF convey natural aesthetics that many customers associate with sustainability. For retail or corporate buyers, offering a product that feels more permanent than single-use alternatives supports brand values around quality and environmental mindfulness.

Pricing and margins

From a procurement standpoint, wooden coasters provide a favorable cost-to-perceived-value ratio. They’re inexpensive to produce in bulk yet retail at a margin that supports profitable bundles and gifting strategies. For merch sellers, a well-designed coaster can often carry a markup that includes packaging and creative design costs and still remain attractive to end customers.

Seasonal and campaign ideas

- Holiday gift sets: pair ceramic or stone coasters with a branded mug for limited-time bundles.

- Brewery release series: issue artist-designed coaster sets for numbered seasonal beers.

- Corporate gifting tiers: offer standard cork-backed coasters for staff and premium ceramic sets for executive clients.

- Café loyalty programs: give away coasters as part of milestone rewards to keep customers returning.

How I choose a supplier and why ours aligns with buyers’ needs

When evaluating vendors, I look for consistent print quality, reliable material options, and transparent packaging specs. Our production supports multiple substrates and printing methods, enabling us to match design intent with the correct surface treatment. We prioritize dimensional stability and finishing so coasters stack, ship, and display cleanly. For buyers who need repeatable quality and reasonable MOQ flexibility, this combination minimizes risk and keeps replenishment predictable.

Testing and sample strategy

Before committing to full runs, I always order a sample pack covering each material type I plan to offer: one cork-backed MDF, one pure cork, one rubber-backed, and a premium ceramic or stone piece if retail positioning requires it. This lets me validate print color, backing adhesion, and real-world feel. Samples also become useful marketing assets for product photography and unboxing content.

Common objections and practical answers

- “Will prints fade with use?” Proper sublimation and heat-transfer processes applied to coated surfaces yield very good durability. I recommend specifying a tested coating when ordering photographic or gradient-heavy designs.

- “Do coasters curl or warp?” Quality wooden and MDF coasters that are correctly dried and sealed remain flat under normal service conditions. Avoid low-grade unsealed boards for environments with frequent temperature changes.

- “Are these slip-prone?” Cork and rubber backing mitigate slipping. For bar use, choose rubber backing; for tabletop elegance combined with functionality, cork is the best compromise.

Retail presentation and merchandising tips

Display coasters in small stacks, framed sample displays, or flat-lay shelving where customers can see both the printed side and the backing. For online listings, include close-up shots of the printed surface, the backing texture, and lifestyle images showing coasters in use (on a café table, bar counter, or as part of a gift set).

A well-produced printed coaster is a small product with outsized marketing and utility benefits. It sits at the intersection of branding, functionality, and retail potential. For cafés, bars, hotels, merch sellers, and corporate buyers, the right choice in material, print method, and SKU mix turns coasters into a repeatable revenue and visibility driver.

If you’re curating an assortment for retail or outfitting venues with branded items, I recommend starting with a core cork-backed MDF coaster for daily service, adding a ceramic or stone retail SKU for higher-margin gift sets, and experimenting with limited-run printed fabric or pure cork pieces for seasonal promotions. Each of these choices supports a distinct audience need while keeping production and logistics manageable — and ensures your brand is literally part of every table conversation.

Our Factory

Founded in 2014, Qlychee focuses on the design and manufacture of wooden products and has built a complete design-to-sales system supported by an advanced production line. We accept both custom sample orders and large-scale mass production.

The production flow is highly automated, combining CNC cutting, laser engraving, precision edge-banding, and automated spray finishing to deliver consistent workmanship and reliable structural performance.

Material selection, dimensional accuracy and surface treatment are strictly controlled. We offer a range of wood and finish options (solid wood, plywood, MDF, eco-friendly paints, wood wax oil, etc.) and support rapid prototyping and functional testing from customer drawings or samples.

With stable production capacity and a robust quality management system, Qlychee provides one-stop services—from concept and sample validation to high-volume manufacturing—for product categories such as small household wooden items, gift items, home décor and educational toys.

Advanced Production Line

Why Partner with Qlychee

Shipping & Delivery

Get A Quote Now

Get A Quote Now