sales@qlycheecrafts.com

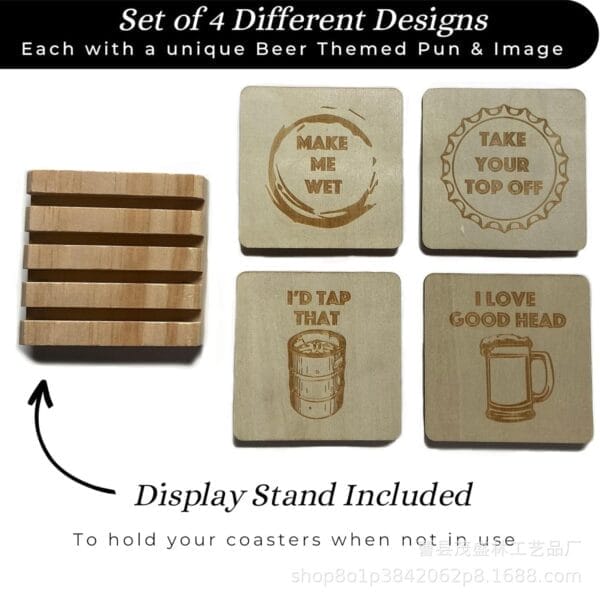

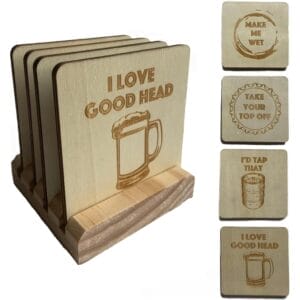

Engraved Wooden Beer Coaster Set — 4 pcs with Stand | Custom Laser-Engraved Wooden Coasters for Bars & Gifts

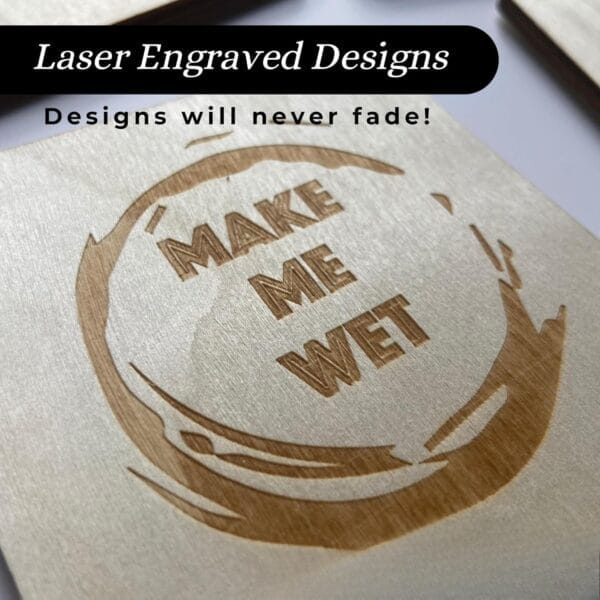

- Solid natural wood construction with precision laser engraving for consistent detail and minimal finish variation — ideal for high-volume orders of engraved wooden coasters. Durable surface resists ring marks; compatible with water-based sealants for added protection.

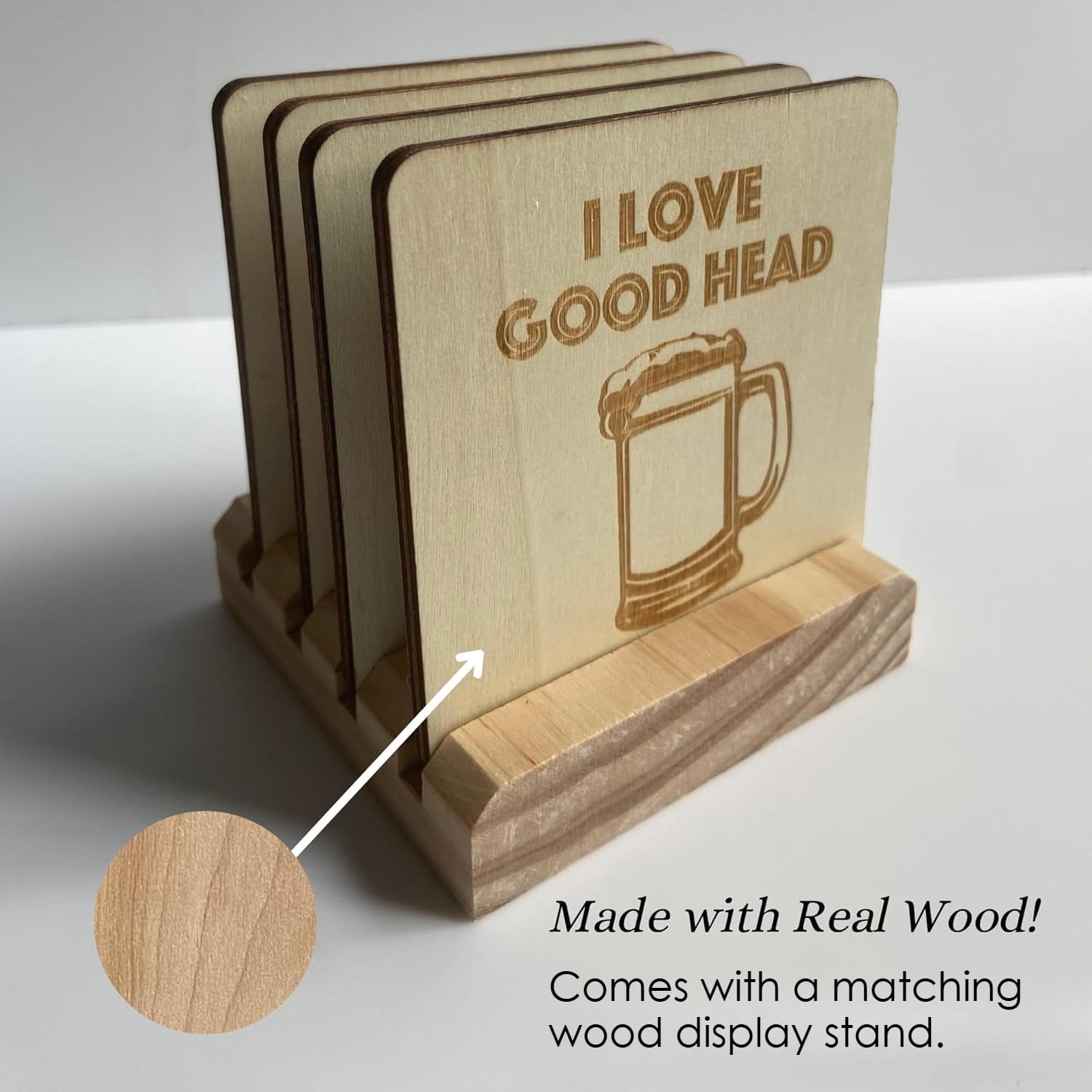

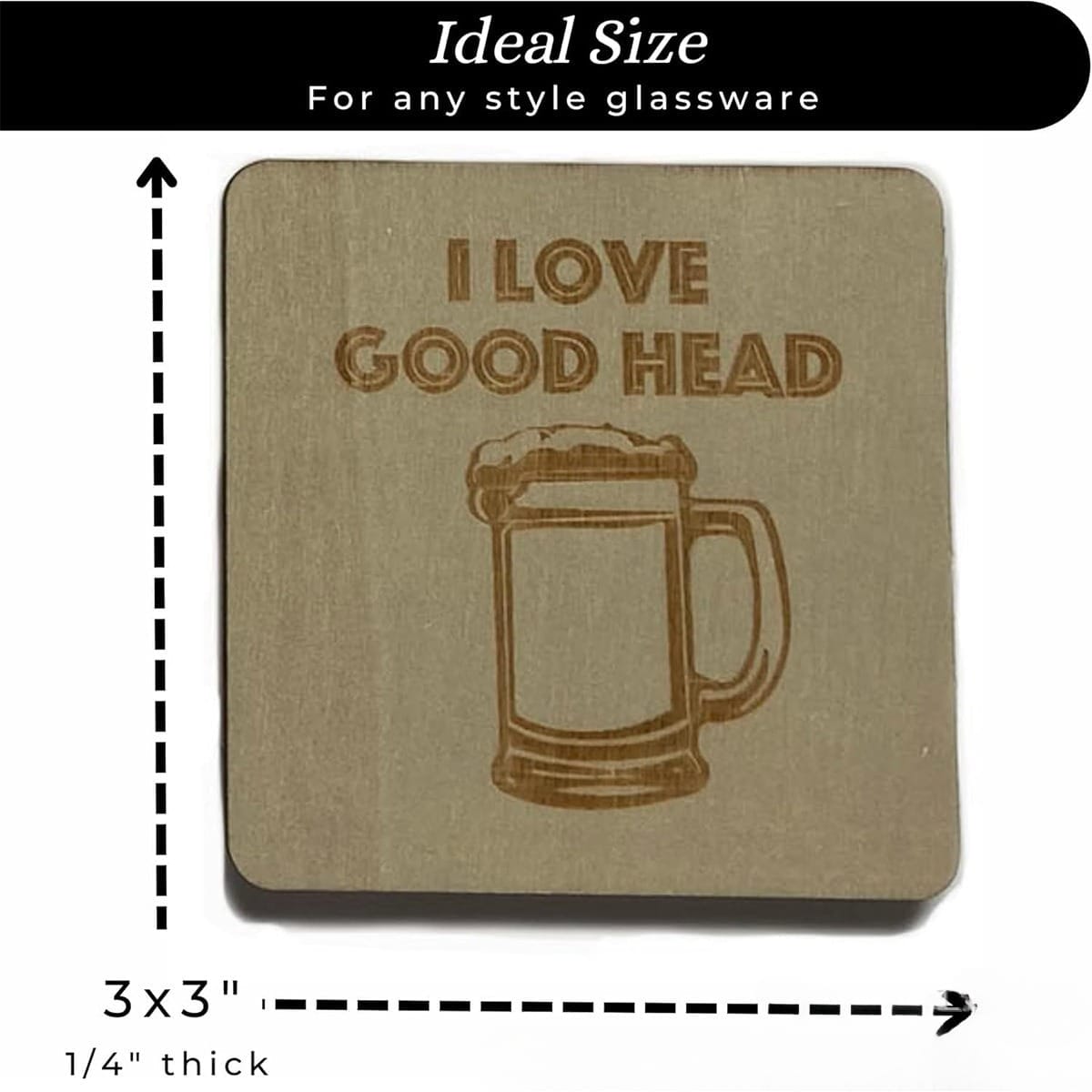

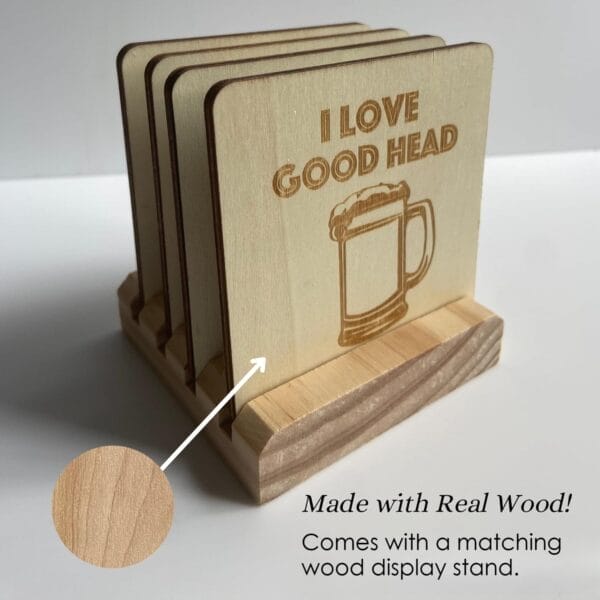

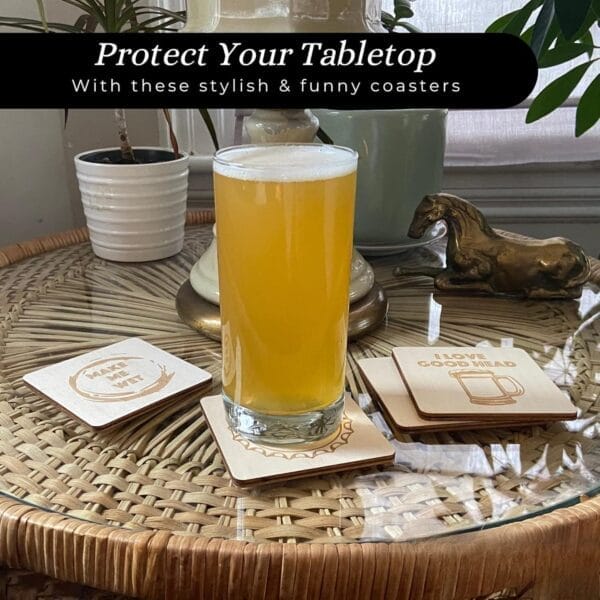

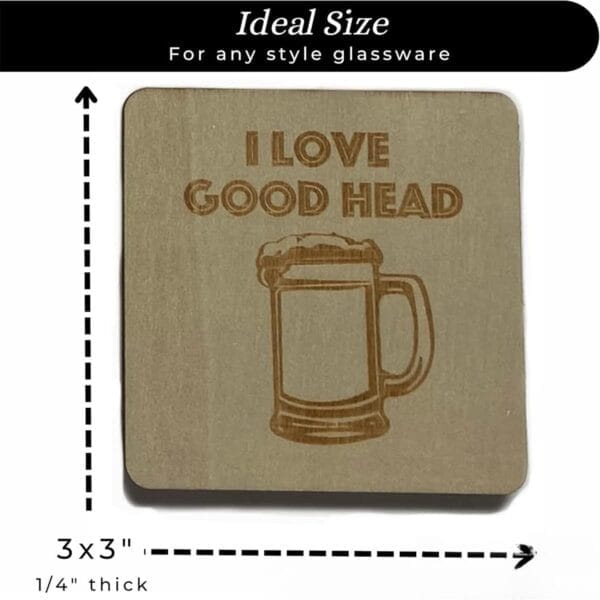

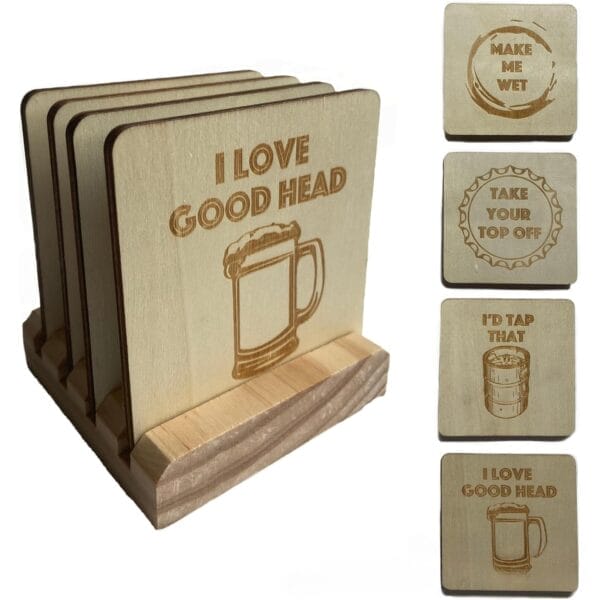

- Compact 7.6 × 7.6 cm tiles sold as a 4-piece set with matching stand; designed for efficient retail display and hospitality use as Wooden Beer Coasters. Stackable, uniform sizing reduces packing time and shelf space, lowering per-unit handling costs.

- Three shape options (round, square, irregular) plus MOQ 100+ and scalable OEM laser-logo placement let you tailor products for brewery merch, bar chains, and promotional campaigns without large inventory risk.

- Lightweight yet sturdy design lowers freight cost per unit and simplifies distributor replenishment. Consistent thickness supports automated packing and predictable fulfillment for B2B channels.

- Natural wood aesthetic comes gift-ready with bulk packaging options and quality checks; ideal for seasonal bundles, corporate gifts, and retail displays. Request samples and OEM quotes to confirm lead time and customization details.

- One-stop service from design to delivery

- Free design support for beginners

- Production progress tracking

- Custom laser cutting & printing

Product Name Engraved Wooden Coasters SKU 171799 Place of Origin China Zhejiang Material Wood Product Type Custom Wooden Coasters Technique Laser Engraving/Laser Cutting/UV Printing Theme Brewery Merchandise, Bar & Taproom Decor, Rustic Gift, Craft Beer Accessories, Corporate Gifting, Promotional Giveaways, Seasonal Limited Editions, Souvenir & Tourist Shop Items, Eco-Friendly Home Accents, Minimalist Tabletop Decor Use Protect Tabletops From Moisture, Coaster Sets For Beer Glasses, Bar & Restaurant Tabletop Protection, Taproom Retail Merchandise, Corporate Event Gifts, Promotional Branded Giveaways, Hotel And Hospitality Amenities, Gift Box Bundles, E‑Commerce Product Offerings, Point‑Of‑Sale Impulse Add‑On Packaging Method OPP bag/Carton Package OEM/ODM Warmly Welcomed Mode of shipment By air or by sea or your request Logo Laser engraving, UV Customized Logo Size & Color 7.6*7.6cm, Customized Weight 200g Sample Available MOQ 100 Pieces Shape Customized How I Help Businesses Scale with Engraved Wooden Coasters

I work with retailers, brewery merch managers, hospitality purchasers, and promotional suppliers who need a reliable supplier for high-quality engraved wooden coasters. Over the years I’ve learned what matters most: consistent engraving detail, predictable lead times, low MOQ, efficient packaging, and product stories that convert on shelves and online. This article explains, from product design through fulfillment and marketing, how these engraved wooden coasters deliver value across channels — and how you can use them to grow revenue, reduce returns, and strengthen your brand.

Why wooden coasters?

Wood brings tactile warmth, clear visual contrast for laser engraving, and a natural aesthetic that resonates with craft breweries, independent retailers, and corporate-gift buyers. We offer a 4-piece set (7.6 × 7.6 cm each) with a matching stand, multiple shape options (round, square, irregular), and OEM laser-logo capabilities with MOQ 100+. Typical lead time for bulk production is 25 days. Below I cover technical details, customer segments, packing and logistics, merchandising tips, pricing and margins, sustainability notes, quality control, and common buyer questions.

Product fundamentals and manufacturing advantages

- Material and finish: These are solid wood coasters with a clean, natural surface that takes laser engraving exceptionally well. The grain gives each piece character while precision laser settings ensure crisp logos and text. When finished with a compatible water-based sealant, the top resists drink rings and light stains while remaining safe for laser detail.

- Laser engraving consistency: For B2B buyers, repeatability is everything. I optimize engraving files and machine parameters to produce consistent depth and contrast across large batches. That means your engraved wooden coasters look identical in retail sets and branded giveaways, reducing customer complaints and returns tied to inconsistency.

- Modular SKU design: A single core mold and board thickness lets us offer round, square, and irregular shapes with the same tooling. That lowers setup cost and shortens ramp time for custom runs. Because each tile is 7.6 × 7.6 cm in the base SKU, you get predictable packing density and simplified display planning for stores and distributors.

Who buys these coasters — and why they convert

- Breweries and taprooms: Craft beer venues want merch that reflects their brand DNA. A quality Wooden Beer Coasters set with a laser-engraved logo reads as artisanal and collectible. Customers buy sets as souvenirs, while bars use coasters as functional tabletop merch. With MOQ 100+ you can run seasonal drops or limited-edition releases without overcommitting inventory.

- Hospitality groups and bars: Chains and independent bars value durable, attractive coasters that protect tables and promote the venue. Laser-engraved brand marks are permanent and survive repeated cleaning, so coasters continue to market the bar long after the sale.

- Retail and gift shops: Natural wood gifts fit in lifestyle stores and museum shops. Coaster sets sell well in curated gift sections and as add-ons at the point of sale. The included stand transforms a set into a display-friendly unit, boosting perceived value and basket attachment.

- Promotional & corporate buyers: For corporate gifting, the balance of elegance and affordability is key. Custom engraved wood coasters let companies issue branded gifts for clients, events, or employee appreciation while maintaining a modest per-unit cost and a premium look.

- E‑commerce merchants and distributors: Sellers on platforms like Amazon, independent webshops, or wholesale distributors appreciate the low weight, standard cubic size, and stackable packaging — all reduce shipping costs and simplify FBA or multi-channel fulfillment.

Design and customization options that matter

- Laser logo placement and artwork preparation: To preserve brand legibility, I recommend vector artwork (SVG, AI, EPS). Engraving depth and contrast depend on wood species and grain orientation; I provide test engraves for approval. Using consistent font weights and simplified logos yields the sharpest result on every set of laser engraved wood coasters.

- Shape and SKU strategy: Offer a standard SKU (7.6 × 7.6 cm square) and optional shapes as special SKUs. This keeps inventory manageable while letting retailers rotate fresh shapes for seasonal promotions.

- Packaging choices for retail and corporate channels: Retail-ready gift boxes raise perceived value and justify higher MSRP. For promotions and bulk orders, simple bulk-packed trays or polybags reduce cost. We can supply both — gift boxes for retail, stackable trays for distributors — meeting the needs of both channels while keeping MOQ at 100+.

- Finishes and protective coatings: A light water-based sealant improves stain resistance without hindering laser clarity. I avoid heavy lacquers that can trap moisture; instead I use finishes compatible with laser marking and safe for food-contact surfaces.

Operational and fulfillment considerations

- MOQ and lead times: MOQ 100+ keeps the barrier-to-entry low for small brewers and boutique retailers. Standard bulk lead time is 25 days, which includes engraving, finishing, and packaging. That lead time balances customization and production efficiency for reliable planning of seasonal campaigns.

- Packing density and freight: Because each coaster is compact and lightweight, palletization yields high cubic efficiency. Stackable sets on stands pack tightly, reducing freight cost per unit and lowering landed cost for international distributors.

- Quality control and returns: I implement sample-first approval, inline QC during engraving, and final inspection before shipment. This reduces defects and returns, particularly important for bulk buyers and FBA channels where complaints translate to fees and reputation risk.

Marketing and merchandising strategies

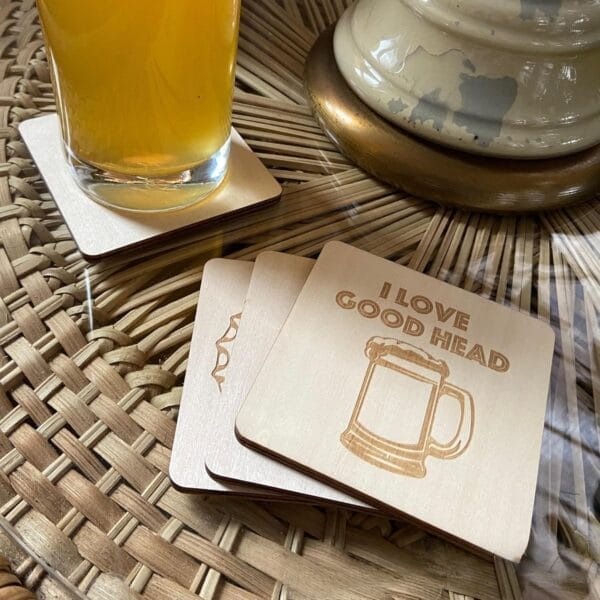

- Point-of-sale merchandising: The included stand doubles as an on-shelf display — display one set unboxed so customers can touch and see engraving quality, while other sets are boxed for purchase. This tactile experience is powerful for wood engraved coasters, especially in gift-focused stores.

- Bundling and cross-sell ideas: Pair coaster sets with glassware, beer samplers, or bar towels to create gift bundles. For retail, a “taproom starter pack” (coasters + branded pint glass) increases average order value and leverages the coaster’s strong front-of-store appeal.

- Digital product content: High-quality close-ups of the engraving, lifestyle images showing coasters in use, and a short product video of the engraving process increase conversion rates. Use detailed specs and clear SKU images for distributors to ease re-listing.

- Promotional calendar plays: For breweries, align special-edition coaster runs with seasonal beer releases — Oktoberfest shapes in fall, summer-themed irregular shapes for summer sessions. For corporate buyers, push holiday-ready gift-boxed sets during Q3–Q4 planning windows.

Pricing, margins, and commercial models

- Cost drivers and margin opportunity: Major cost drivers are wood material, engraving time, and packaging. Choosing a standard size and surface finish lets you maximize margin while offering customization as an upcharge. As a rule, simple custom engraving at MOQ 100+ enables healthy wholesale margins for retailers and comfortable B2B pricing for corporate buyers.

- Suggested wholesale vs retail pricing: Wholesale buyers typically target 2.5–4x margin on cost to cover overhead and distribution. For example, if per-set landed cost including packaging is X, offer recommended MSRP at 2.5–3x X for retail channels; distributors sourcing at bulk should expect lower per-unit prices at higher quantities. The included stand and gift-ready packaging support a higher MSRP than loose coaster SKUs.

- Private label and OEM models: I support artwork approvals and proofing, meaning private-label buyers can order branded wooden coasters engraved with their logo and packaging. Private label runs at MOQ 100+ are feasible for testing market traction without large inventory risk.

Sustainability and material sourcing

- Wood sourcing and end-of-life: Wood is renewable and bio-based. If you require chain-of-custody documentation or FSC-certified material, I can coordinate sourcing options to match your sustainability claims. The natural wood aesthetic is a strong selling point for eco-minded retail buyers who want an “eco-feel” product.

- Packaging and recyclability: Choose recyclable gift boxes and avoid mixed-material blister packs. Stackable, cardboard internal trays not only save space but are also easy to recycle. Sustainable packaging is increasingly valued by end consumers and corporate buyers.

- Durability vs biodegradability: A light protective finish extends product life and reduces waste; at end of life, untreated wood components can biodegrade. Be careful with heavy polymer coatings if biodegradability is a priority.

Quality assurance and compliance

- Sample approval workflow: I recommend buyers request a printed sample with their exact logo before full production. The sample confirms engraving contrast, placement, and finish behavior; sign-off minimizes rework.

- Inspection checkpoints: Incoming material inspection for board defects, inline check for engraving registration, and final pack verification for counts and packaging integrity. These steps minimize defects that can become costly disputes for B2B clients.

- Food-contact and safety notes: While coaster surfaces are not intended for long-term food contact, surfaces are finished with water-based sealants compatible with incidental contact. If you need formal food-contact certifications, specify during inquiry so materials and finishes can be adjusted and tested accordingly.

Use cases and channel-specific guidance

- Bars & taprooms: Use the coasters as merch and daily tabletop protection. Sell single boxed gift sets at the bar and offer a discounted multi-set pack online. Limited-edition engraving tied to seasonal brews drives repeat purchases.

- Restaurants and cafés: Train staff to rotate coaster designs for seasonal campaigns. Coasters with a neutral brand mark or local landmark art resonate with locals and tourists alike.

- Retail specialty stores: Create tiered displays: premium boxed sets at eye level and simple bulk packs near checkout for impulse purchases. Emphasize handcrafted laser detail in signage.

- Corporate & promotional buyers: Offer bundled fulfillment for events: coasters in custom boxes, shrink-wrapped for easy distribution. Provide mockups and a digital proofing step for approval. Lead times typically 25 days; plan early for holiday campaigns.

How I approach customization projects

- Brief intake and proofing: I start with a quick intake form to capture logo files, preferred shapes, packaging choices, and target quantities. Next, I produce a physical or digital sample proof for approval.

- Tooling and setup: Because engraving is digital, setup costs are low relative to other customization methods. Vector artwork translates directly to engraving vectors, so turnaround from proof approval to production is fast.

- Scaling and repeat orders: After the first run, I store engraving settings and approved proofs to accelerate repeat orders. This reduces production variance and shortens lead times for restocks.

Marketing copy and product listing essentials

- Product title best practices: Use concise, keyword-rich titles like “4‑pc Laser Engraved Wooden Coaster Set — 7.6×7.6 cm with Stand.” That targets search terms while remaining punchy for catalog listings.

- Bullet icons for product pages: Call out size, set count, finish, SKU, MOQ 100+, and lead time (25 days). Buyers scan pages quickly; bullets help procurement professionals evaluate fit fast.

- High-converting product descriptions: Combine tactile language with specs. Example: “Natural wood tiles precisely laser engraved wooden coasters — four coasters plus a matching stand. Each tile measures 7.6×7.6 cm and is finished with a water-based sealant.”

- SEO and keyword strategy: Use one main phrase — engraved wooden coasters — frequently but naturally through headers, intro, and bullets. Sprinkle secondary phrases such as laser engraved wood coasters and Wooden Beer Coasters in descriptive paragraphs, image alt text, and meta descriptions to cover related search intent.

Practical merchandising examples and visuals

- In-store demo: Remove one set from the box and display on a small riser next to boxed sets. Add a shelf talker describing customization options and MOQ 100+ to drive B2B interest.

- Photography brief: Capture close-ups of engraving detail, lifestyle shots with glasses in use, and a packaging shot that shows gift-ready presentation. Include a top-down image showing uniform size for grid comparison.

- Social and email campaigns: For breweries, announce a new coaster run tied to a beer release. For corporate buyers, send targeted emails with mockups for logo placements and bulk pricing tiers.

Handling objections and frequently asked questions

- “What if my logo doesn’t engrave well?” I provide a preflight check of logos and suggest simplified or alternate marks if thin strokes won’t reproduce reliably. Vector artwork and higher contrast designs work best.

- “How durable are the engravings?” Laser engraving is permanent and holds up to normal use. The protective water-based finish reduces staining without masking engraved detail.

- “Can you handle repeat orders?” Yes — I keep production parameters and proofs for efficient repeat runs. Typical restock lead times drop after the first order due to stored settings.

- “What about color or printing?” These coasters are optimized for engraving. If you need full-color printing, we can discuss hybrid packaging prints or separate printed SKUs, though that changes cost and production steps.

Packaging, shipping and fulfillment best practices

- Pack for protection and speed: Use internal cardboard trays to keep sets flat and protect engraving. For retail, include a small insert with care instructions and a brand story. For corporate shipments, supply shipping-ready cartons with clear packing lists.

- Freight efficiency: Leverage palletized shipments for large orders to minimize per-unit freight cost. Small runs can ship via parcel with protective inner packaging to avoid transit damage.

- FBA and cross-border prep: If selling in marketplaces, advise labeling and carton compliance up front. Pallet consolidation and proper box counts prevent costly FBA rejections.

Performance metrics B2B buyers care about

- Return rates: Good engraving repeatability and protective finishes reduce returns tied to perceived quality issues. QCs at three production stages further lower dispute incidence.

- Lead time adherence: With a stated 25-day production window, I track order milestones and provide weekly status updates so procurement teams can plan promotions or shipments.

- Cost per unit and landed cost: Because the product is light and pack-efficient, landed costs remain competitive for international distributors. I provide FOB, EXW, and CIF estimates to support buyer negotiation.

Creative product ideas to expand SKU offerings

- Limited-edition artist series: Collaborate with local illustrators to create collectible coaster sets that rotate seasonally and drive repeat retail traffic.

- Multi-material combos: Pair wooden coasters with cork backing or felt pads for extra table protection. Cork can be added as a secondary SKU to increase perceived value.

- Coaster gift bundles: Combine coasters with branded glassware, bottle openers, or recipe cards for a higher-ticket product aimed at tourists and gift shoppers.

Checklist for buyers before ordering

- Confirm artwork in vector format.

- Approve a physical or digital sample.

- Choose packaging type: gift box vs bulk tray.

- Confirm MOQ 100+ and final lead time (25 days).

- Request pre-shipment photos or a QC report.

Case studies and outcomes I’ve seen

- Brewery X: Launched a limited coaster run for a seasonal beer release with 200 sets. The engraved mark became a sought-after souvenir and boosted taproom merch revenue by 18% that quarter.

- Retailer Y: Introduced boxed coaster sets in a lifestyle store at 3x markup over cost. Cross-sold with glassware to create a branded gift bundle that increased AOV by 22%.

- Corporate client Z: Ordered 1,000 engraved sets for conference gifting. Pre-approved samples and a fixed lead time meant zero return claims and fast distribution at the event.

Final recommendations for procurement and merchandising

- Start with a sample and a small launch order (MOQ 100+) to validate customer response.

- Use the included stand to create a visible in-store focal point; a single unboxed display set is worth multiple boxed units on shelves.

- Plan seasonal or limited-edition runs to maintain interest and justify higher ASRPs.

- Keep artwork simple and bold for the best engraving results.

If you’re ready, I can prepare a sample approval sheet, mockup images for your e‑commerce page, and a wholesale quote breakdown based on your target quantity and packaging preference. Reach out to request artwork specs, sample shipping, and precise lead-time scheduling for your first MOQ 100+ order of engraved wooden coasters.

Our Factory

Founded in 2014, Qlychee focuses on the design and manufacture of wooden products and has built a complete design-to-sales system supported by an advanced production line. We accept both custom sample orders and large-scale mass production.

The production flow is highly automated, combining CNC cutting, laser engraving, precision edge-banding, and automated spray finishing to deliver consistent workmanship and reliable structural performance.

Material selection, dimensional accuracy and surface treatment are strictly controlled. We offer a range of wood and finish options (solid wood, plywood, MDF, eco-friendly paints, wood wax oil, etc.) and support rapid prototyping and functional testing from customer drawings or samples.

With stable production capacity and a robust quality management system, Qlychee provides one-stop services—from concept and sample validation to high-volume manufacturing—for product categories such as small household wooden items, gift items, home décor and educational toys.

Advanced Production Line

Why Partner with Qlychee

Shipping & Delivery

Get A Quote Now

Get A Quote Now