What is manufactured wood? Manufactured wood consists of engineered products like MDF, plywood, OSB, and cross-laminated timber.

These materials are created through processes that combine wood fibers, strands, or layers with adhesives under heat and pressure. They’re designed to maximize resource efficiency. Meanwhile, they offer superior stability and consistency compared to natural wood.

These products serve diverse applications in construction and wooden crafts. Understanding their unique properties will enhance your ability to select the right material for specific projects.

Key Takeaways

- Manufactured wood is engineered material made from wood fibers, strands, or veneers combined with adhesives and pressed under heat and pressure.

- Common types include Medium Density Fiberboard (MDF), plywood, Oriented Strand Board (OSB), and Cross-Laminated Timber (CLT).

- These products maximize resource efficiency. Because they utilize wood waste and fast-growing trees while reducing deforestation.

- Manufactured wood offers cost advantages over solid wood. They provide consistent quality for construction and furniture applications.

- These materials are generally more resistant to warping. They provide uniform strength and come in standardized sizes for various projects.

What Is Manufactured Wood? 6 Main Types of Wood

When you explore manufactured wood products, you’ll encounter several distinct types with unique properties and applications.

Medium Density Fiberboard (MDF)

Medium-Density Fiberboard (MDF) is a cornerstone of modern woodworking. It represents a significant advancement in engineered wood products.

This manufactured wood material is created through a precise combination of wood fibers, wax, and resin. Under intense heat and pressure, these components form smooth, uniform panels that excel in detailed applications.

MDF’s versatility shines through its range of available thicknesses, from 1/4 inch to 1 inch. It’s ideal for indoor cabinetry and molding projects. So it’s essential to keep it away from moisture.

Remember to maintain proper ventilation when working with MDF. Because its adhesives can release VOCs during the fabrication process.

Plywood Construction and Uses

Three essential layers form the foundation of plywood’s remarkable strength and versatility in modern construction.

Each layer is precisely aligned at right angles, creating a manufactured wood product that resists warping and splitting. When selecting plywood for your project, you’ll discover various grades and thicknesses available.

For outdoor applications, choose marine or exterior-grade plywood that effectively withstands moisture.

The sustainable manufacturing process uses wood veneers efficiently. This makes plywood an environmentally conscious choice. You can rely on plywood’s durability for wood flooring, walls, roofs, and furniture projects that demand structural integrity.

Oriented Strand Board (OSB)

Oriented Strand Board stands as one of today’s most innovative manufactured wood solutions.

This engineered wood product is commonly used in construction projects. It serves as reliable sheathing for walls, roofs, and floors. The panels are available in thicknesses from 1/4 inch to 3/4 inch. They deliver exceptional structural integrity through their unique manufacturing process.

Unlike traditional plywood, OSB’s uniform composition resists warping while maintaining consistent strength.

Manufacturers create OSB by bonding wood strands in specific orientations with waterproof adhesive. This makes it both durable and sustainable through the efficient use of wood by-products.

Particle Board Manufacturing Process

Particle board represents another significant advancement in manufactured wood technology. It builds upon the success of products like OSB.

The manufacturing process begins with collecting wood particles, including sawdust and chips. These materials are then mixed with special resins and hardeners. You’ll find these materials compressed under intense heat and pressure to create uniform, dense boards.

The process enables manufacturers to produce particle board with varying densities, catering to diverse requirements.

You can see this manufactured wood commonly used in cabinets, shelving, and furniture. It offers an economical alternative to solid wood while promoting sustainability through waste reduction.

Cross-Laminated Timber Applications

Cross-laminated timber (CLT) is among the most innovative developments in manufactured wood technology. It stands as a revolutionary building material. This engineered wood product transforms modern construction with its versatile applications and sustainable properties.

| Application | Benefits |

|---|---|

| Multi-story Buildings | Superior structural stability and lightweight design |

| Thermal Solutions | Enhanced insulation and energy efficiency |

| Rapid Construction | Prefabrication reduces assembly time |

| Green Building | Environmentally friendly alternative to concrete |

CLT’s growing popularity in construction stems from its exceptional strength-to-weight ratio and thermal performance. You can expect this material to continue revolutionizing sustainable architecture while meeting strict building codes and environmental standards.

High-Density Hardboard Properties

When manufacturers compress wood fibers under intense heat and pressure, they create high-density hardboard‘s remarkable strength and durability.

This wood product offers exceptional resistance to impact, with densities ranging from 45 to 65 lbs per cubic foot. Its smooth, uniform surface makes it perfect for painting and veneering applications.

Unlike traditional solid wood or hardwood, high-density hardboard won’t easily warp or swell in moisture-prone environments.

You can use this versatile material as a cost-effective alternative to plywood in wall paneling, door skins, and cabinetry.

Its combination of durability and affordability makes it an excellent choice for both furniture and interior applications.

Benefits and Advantages of Engineered Wood

The advantages of engineered wood extend far beyond its cost-effective nature. It offers exceptional versatility in design and application. The material’s lightweight properties make it easier to transport and install than traditional lumber.

| Feature | Benefit | Application |

|---|---|---|

| Melamine Coating | Moisture Resistance | Kitchens & Baths |

| Custom Design | Color Options | Furniture |

| Recycled Content | Eco-Friendly | Green Building |

When choosing engineered wood, you select a material that combines durability with practicality. The manufacturing process ensures consistent quality throughout each piece. It eliminates the unpredictable variations inherent in natural wood.

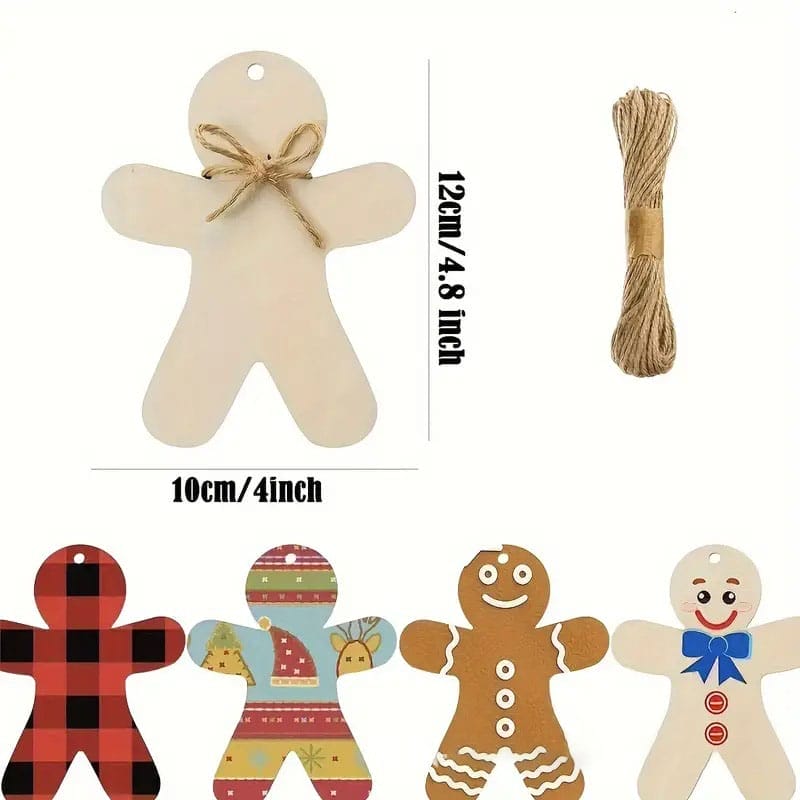

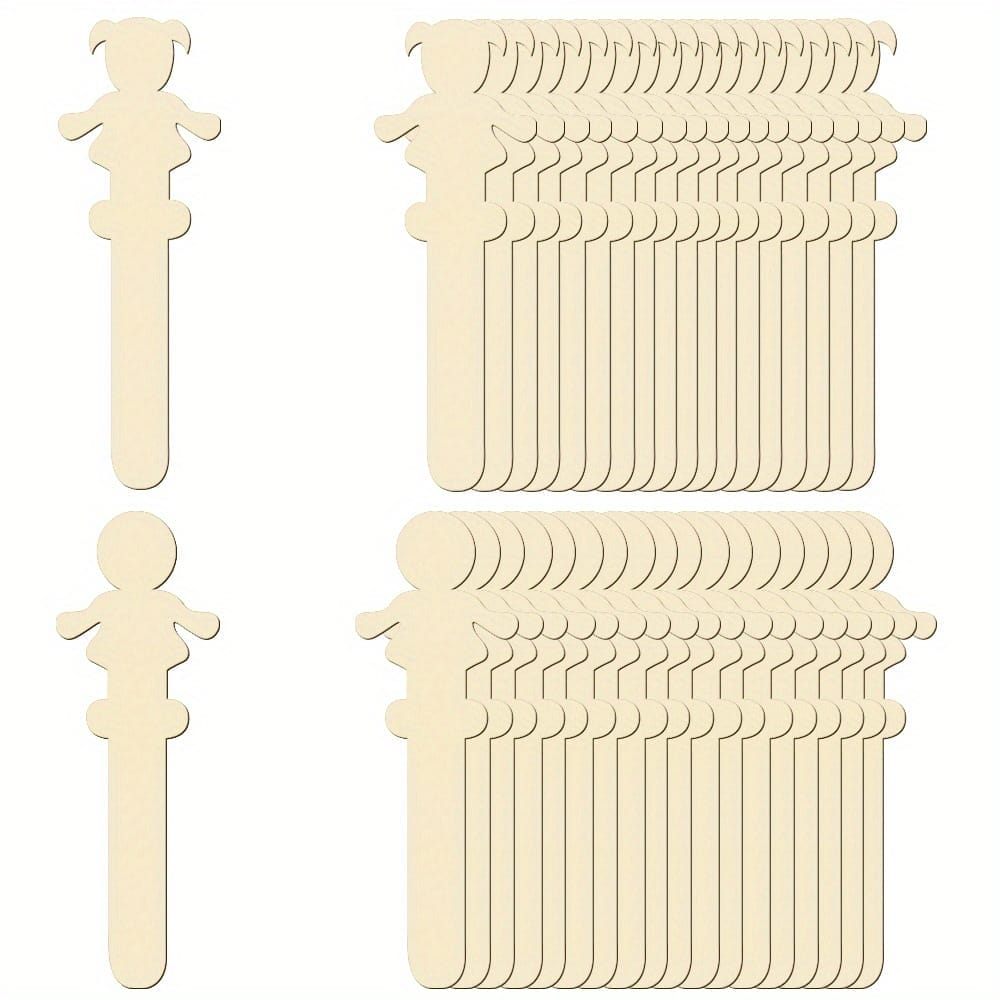

Applications in Wooden Crafts

Manufactured wood is widely used in wooden crafts. This is due to its superior stability, consistent quality, and excellent workability. It meets the demands of detailed craftsmanship while offering environmental and cost benefits. It’s a key material choice for modern woodworking projects.

| Application Area | Specific Uses | Advantages |

|---|---|---|

| Furniture Making | Tables, chairs, cabinets, bookshelves, bed frames | Excellent dimensional stability, smooth surface,easy to process and finish |

| Decorative Crafts | Wall hangings, carved items, photo frames | Easy to cut and carve, allows for detailed designs |

| Interior Decoration | Wall panels, door panels, wainscoting, ceiling panels | Versatile shapes, moisture resistant, easy to install |

| Toy Manufacturing | Wooden puzzles, building blocks, children’s furniture | Made from eco-friendly materials, smooth surface, high safety |

| Model Making | Architectural models, art models, craft models | High precision, easy to shape and paint, lightweight |

| Display Stands & Fixtures | Product display racks, exhibition cabinets | Stable structure, consistent appearance, customizable design |

| Kitchenware & Utensils | Cutting boards, trays, utensil holders | Moisture resistant, warp resistant, easy to clean and durable |

| Custom Furniture & Design Elements | Personalized furniture panels, carved decorative trims | Wide range of colors and textures, supports creative design ideas |

Environmental Impact and Sustainability

The environmental footprint of manufactured wood takes center stage in sustainability discussions. Its production emphasizes resource efficiency through the utilization of wood by-products and fast-growing tree species.

| Aspect | Environmental Impact | Sustainability Factor |

|---|---|---|

| Materials | Uses recycled content | Reduces deforestation |

| Production | Requires adhesives | Energy-efficient process |

| Waste | Minimizes wood waste | Promotes circular economy |

| Growth | Market expanding rapidly | Increases eco-alternatives |

| Future | Projected $344.67B by 2025 | Drives green innovation |

Manufactured wood offers significant environmental benefits through resource conservation. But you should also consider its potential drawbacks, including chemical adhesives that may affect indoor air quality.

Cost Analysis and Market Trends

Recent market analysis reveals dramatic growth in the manufactured wood industry, with valuations soaring past $243.93 billion in 2020. Market trends indicate continued expansion, with projections reaching $344.67 billion by 2025.

Manufactured wood products offer significant cost advantages through efficient resource utilization. You’re benefiting from lower prices compared to solid wood, while manufacturers optimize their use of raw materials.

The industry’s focus on sustainability transforms waste into valuable products, meeting growing environmental demands. Transportation costs remain lower due to the material’s lightweight nature. This makes it an increasingly attractive option for construction and furniture applications.

Final Words: What Is Manufactured Wood?

Manufactured wood remains your sustainable and cost-effective choice. Its versatility extends across residential, commercial, and industrial applications. As technology advances, you’re seeing improved durability and environmental benefits in these engineered products.

Consider manufactured wood for your next wooden crafts project. We offer a wide variety of products, available for wholesale and customization. Contact us for more information.

FAQs

Is Manufactured Wood Real Wood?

No, manufactured wood isn’t real wood. It’s a composite material you’ll find made from wood fibers, chips, or sawdust mixed with adhesives. While it looks like wood, it’s engineered rather than natural.

What Are the Disadvantages of Manufactured Wood?

It contains toxic chemicals, can’t be recycled, lacks structural strength, and has a shorter lifespan. It may warp in extreme conditions like heat and humidity.

Is Manufactured Wood the Same as Particleboard?

No, manufactured wood isn’t the same as particleboard. Particleboard is a type of manufactured wood. You’ll find other varieties, such as MDF and plywood, that are also manufactured woods with different properties and uses.