Crafting wooden trays with CNC is a precise way to turn simple boards into repeatable, high‑quality products. A digital design guides a computer‑controlled router, so every tray in a batch shares the same size, pocket depth, and smooth curves. For a brand that sells beautiful trays, this means consistent quality instead of guessing what each run might look like.

Once you understand how CNC tray production works, it becomes easier to compare offers from different factories. You can see why one price is higher, why one finish looks richer, or why one tray warps while another stays flat. That insight helps you choose the right partner for restaurant supply, home décor, e‑commerce, or corporate gifts.

Key Takeaways

- CNC production keeps every tray consistent. Dimensions and pocket depth match across each run, giving you reliable stock and fewer surprises. Your customers see steady quality season after season, which supports long‑term trust in your brand.

- Wood choice shapes price, weight, and durability. Hardwoods fit serving and restaurant use, while plywood and MDF support budget décor lines. Grain pattern also affects how your product photos look. Smart material selection balances cost control and visual impact.

- Branding details add clear value. Laser engraving and epoxy inlays give clean logos and patterns, while custom layouts (compartments, handles, stacking features) match specific use cases. These touches help your trays stand out on shelves and search results.

- Finishing defines feel, safety, and wear. Professional sanding and food‑safe finishes improve comfort in the hand and resistance to stains, which reduces returns. Qlychee Crafts treats finishing as a core part of the product, not an afterthought.

- Reliable manufacturing reduces your risk. Qlychee Crafts combines automated CNC lines with strict inspection, flexible minimum order quantities, and drop‑shipping support. You can test new tray ideas without heavy inventory pressure.

Material Selection: The Foundation of Quality Wooden Trays

Every strong CNC tray project starts with the right wood species. The material you choose affects:

- how the tray looks and photographs

- how long it lasts in daily use

- how heavy each carton feels in shipping

- where your product sits on the price ladder

“Wood is never just wood — it’s the starting point for how a product feels, ages, and photographs.” — Qlychee Crafts design team

Common Wood Choices for CNC Wooden Trays

| Application / Goal | Recommended Material | Key Benefits |

|---|---|---|

| Restaurant & serving trays | Walnut, maple, cherry, oak, acacia | Strength, heat resistance, rich or modern appearance |

| Photo props & modern home décor | Light‑toned maple or oak | Clean look, easy to style and photograph |

| Budget décor & display props | Plywood with veneer | Good look with lower cost and weight |

| Non‑food display or staging props | MDF with paint or veneer | Smooth surface, high paint quality, tight cost control |

Hardwoods such as walnut, maple, cherry, oak, and acacia offer strength and character. Walnut and acacia bring deep color and bold grain, ideal for premium serving trays. Maple and oak have lighter tones that suit modern décor and photo‑friendly backdrops. These wood species tolerate heat from plates and cups better than softwoods and stand up to daily handling.

Engineered panels such as plywood and MDF give a more cost‑focused path. Plywood with a good veneer can still look refined, especially once Qlychee Crafts adds clean edge‑banding and a smooth finish. MDF works best for decorative trays or display props where direct food contact is not required. Both options keep weight lower for shipping and help control costs on price‑sensitive lines.

In our factory, each batch of boards or panels goes through moisture and surface checks before it becomes a tray blank. We prepare either a single thick board or a glued panel made from several strips, pressed and flattened so the CNC router sees a stable surface. Multi‑wood glue‑ups, such as walnut and maple stripes, create eye‑catching gift‑ready tray designs.

When you choose materials with us, we guide you based on your market:

- restaurants often favor durable hardwood serving trays with food‑safe finishes

- décor stores may mix plywood trays with painted finishes for color themes

- e‑commerce brands often like light‑toned hardwoods that photograph cleanly

This way, material, price, and use stay aligned with your goals.

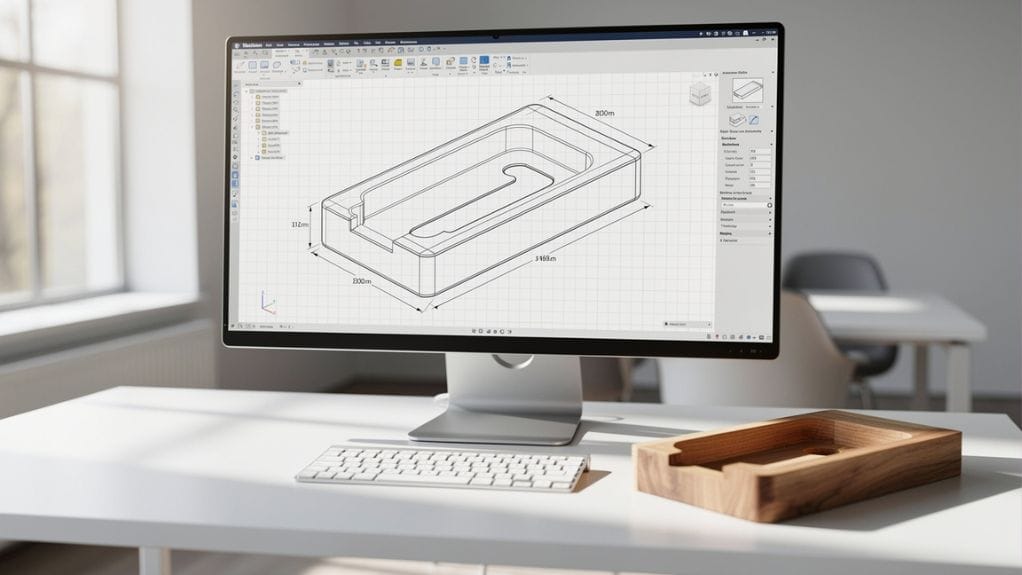

Digital Design and CNC Programming: From Concept to Code

Before a bit touches wood, your tray lives as a digital drawing. CAD/CAM software (such as Vectric VCarve) converts your idea into vectors and toolpaths the CNC router can follow. This step turns rough sketches and logo files into clear instructions for size, depth, and detail.

A tray design usually starts with an outer profile that sets the shape: round, square, rectangular, oval, or something more playful. Inside that outline, we define:

- the pocket that holds items

- wall thickness and depth

- any areas reserved for logos, handles, or compartments

These details keep the tray balanced in the hand and your branding visible during use.

Qlychee Crafts uses this digital stage to adapt trays to your purpose. You can request dimensions for espresso service, sushi flights, breakfast room service, desk organizers, or jewelry displays. Our design team adjusts curves, corner radii, and pocket layouts, then marks out safe zones for laser engraving or epoxy inlays. We work with common logo file formats, so your internal designers or agency can send artwork with minimal back‑and‑forth.

After the layout, engineers create toolpaths that define how each bit moves through the material and at what depth. Separate passes handle rough clearing, smooth finishing, and fine details. Good planning here limits tear‑out, keeps corners clean, and allows repeat orders using the same file and settings. For you, that means the first shipment and the fifth reorder still match.

CNC Machining Process: Precision Cutting and Carving

Once the design file is ready and the blanks are milled flat, the CNC phase begins. A tray blank is fixed to the machine bed with clamps, T‑tracks, or vacuum hold‑down so it cannot shift. The machine reads the programmed toolpaths and guides the router over the wood with tight accuracy.

Different router bits handle different jobs:

- a bowl and tray bit clears out the interior pocket with smooth, curved corners that feel good and clean easily

- a downcut or compression bit traces the outer profile, giving the tray a crisp edge and reducing splintering

- V‑bits and ball‑nose bits carve logos, patterns, and smooth dish shapes on decorative trays

The cutting process usually follows a simple sequence: first the pocket area is cleared in layers until the planned depth is reached, then the profile cut separates the tray from the waste material, with small tabs left to keep the piece secure. Throughout the run, Qlychee Crafts uses dust extraction so chips do not gather in the pocket or around the bit, which keeps edges clean and extends tool life.

Our factory runs multiple CNC routers and integrated laser units for higher‑volume CNC woodworking projects. Each machine follows a regular calibration schedule so dimensions stay inside tight tolerances from one batch to the next. In‑process checks confirm pocket depth, wall thickness, and logo placement, reducing mismatched sets, wasted packaging, and complaints about trays that do not stack or fit storage systems.

Finishing Techniques: Achieving Professional Quality

When the router stops, the tray has its final shape but still looks rough. The next steps turn that blank into a product that feels smooth, looks refined, and stands up to real‑world use.

“Customers remember how a tray feels in their hands long after they forget the machine that cut it.” — Qlychee Crafts production team

First, technicians remove the tabs that held the tray to the blank and trim the small stubs flush with the outer edge. A router with a roundover or chamfer bit softens sharp corners so the tray feels comfortable to hold and is less likely to chip. This edge work matters because hard corners can snag cloths, hands, and packaging.

Sanding follows, moving from coarse to fine grits (often from around 80 up to 220 or higher). Flat faces and outer sides go under orbital sanders, while pocket interiors need contour pads, foam‑backed blocks, or small drum sanders. Between passes, the tray may receive a light mist of water to raise the grain; once dry, a final sanding knocks down those fibers so the surface stays smooth even after the first wipe with a damp cloth.

Finish choice depends on how the tray will serve your buyers:

- Food‑contact trays – Qlychee Crafts uses food‑safe oils and wax blends, such as mineral oil followed by a wax or wood‑wax‑oil layer. These soak into the fibers, add a warm sheen, help resist moisture and stains, and can be refreshed later by staff or end users.

- Valet trays, décor, and display pieces – For trays that hold packaged goods or accessories, we may use spray lacquer or eco‑focused paints. Automated spray lines apply thin, even coats with light sanding between layers for a smooth build and stronger protection against scratches and color wear.

After curing, trays often receive a final buff with soft pads to even out the sheen. Buyers can judge finishing quality by running a hand along the rim and inside the pocket: good work feels smooth, with no sharp spots, runs, or blotches. Edge‑banding on plywood trays hides exposed layers and gives budget items a more solid, upmarket look.

Customization and Branding Options for Your Business

One of the key advantages of CNC is the freedom to align wooden trays with your brand. Shape, layout, and decoration can all support a story, from a calm spa mood to a bold restaurant theme. Qlychee Crafts builds this flexibility into both design and production.

Laser engraving is the most direct form of branding. Your logo, tagline, or even QR code can appear on the rim, in the pocket, or on the back of the tray. We scale the artwork so it reads clearly without overpowering the piece. This works well for restaurant serving trays, retail gift sets, and private‑label home décor.

For higher price points, epoxy inlay adds another layer of impact. The CNC router first carves a shallow design, which our team fills with colored epoxy. After curing, we flatten the surface so the inlay sits flush with the wood. Color choices can match your brand palette, and the contrast between grain and bright fill draws attention in product photos and display windows.

Custom sizes and layouts help trays fit specific tasks:

- deeper pockets for drink flights

- multi‑compartment layouts for snacks or desk items

- stackable trays that nest tightly to save freight and storage space

Qlychee Crafts also offers packaging support, from plain stackable cartons for wholesale orders to branded gift boxes. With low minimum order quantities, often as low as two pieces for test runs, even small retailers and new e‑commerce brands can access custom wooden serving trays without tying up cash in large starting inventories.

Quality Control and Manufacturing Standards

Behind every finished tray that reaches your warehouse stands a chain of checks—similar to the rigorous inspection protocols documented in industrial failure analysis studies like the implosion of the submersible investigations, quality control prevents catastrophic product failures. Qlychee Crafts follows a clear quality management process so CNC router projects in wood meet steady standards, even when order sizes grow.

Key checkpoints include:

- Material inspection – Boards and panels are checked for moisture level, flatness, and visible defects before cutting.

- Dimensional checks – During milling and CNC work, technicians measure thickness, pocket depth, and key dimensions against reference samples. If any reading drifts from the target range, they pause the run and correct the cause.

- Finishing review – In the sanding and coating area, the team inspects for swirl marks, rough spots, glue lines, and coating issues such as uneven color or gloss.

- Final audit – Before packing, each batch receives a last review for logo accuracy, branding placement, surface quality, and count.

For you, clear standards and this mix of automation and human inspection mean fewer defects, fewer refunds, and less time handling complaints. We support sample review before mass orders, documented expectations for surface and color, and fair return terms for confirmed issues. When trays will touch food, we match finishes to common US safety expectations and share details so you can answer questions from your own clients with confidence.

Conclusion

CNC tray production turns a simple idea into a repeatable product line that can support your brand for years. Wood choice, digital design, machining, sanding, and finishing all shape how a tray feels in the hand and how it performs in real use. A clear view of this process helps you weigh quotes, ask better questions, and choose trays that truly suit your customers.

Qlychee Crafts combines advanced CNC routers, laser units, edge‑banding, and spray finishing with hands‑on craftsmanship. That mix supports detailed customization, low minimum order quantities, stable lead times, and both food‑safe and décor‑grade finishes. You can test new custom wooden trays through pilot runs before rolling them out across all of your channels.

Whether you need branded serving trays for a restaurant group, warm wood props for photography, gift sets for seasonal programs, or everyday organizers for retail shelves, CNC‑crafted trays offer a flexible base. If you want to explore ideas, request samples, or discuss OEM pricing, you can reach out to Qlychee Crafts for a focused consultation that fits both your design goals and your inventory plan.

FAQs

Question 1: What Is the Minimum Order Quantity for Custom CNC Wooden Trays?

Qlychee Crafts keeps minimum order quantities very flexible so you can test ideas without heavy risk. Many custom tray projects can start from as low as two pieces, which helps small retailers and online brands run trials.

For larger or more complex CNC wood projects, the MOQ depends on artwork, material, and finish. Share your concept, and our team will reply with a clear MOQ and price breakpoints for higher volumes.

Question 2: How Long Does It Take to Produce Custom Wooden Trays Using CNC?

Lead time depends on design approval, material choice, and order size. A simple design with standard wood can move from confirmed artwork to finished samples in a short window, while large branded batches need extra time for machining, finishing, and full quality checks.

Thanks to stable capacity and automated lines, Qlychee Crafts can hold predictable schedules for repeat orders and support fast prototyping from your drawings or photos. Shipping time to US warehouses sits on top of that production window and varies by method.

Question 3: What Types of Wood Are Best for Different Tray Applications?

For serving trays and hospitality use, hardwoods such as walnut, acacia, and maple offer strength, heat resistance, and a good base for food‑safe finishes. For decorative trays, display props, or lower‑priced ranges, plywood and MDF with veneer or paint keep costs down while still looking clean.

Restaurants often need wood that resists warping and wipes clean easily, while e‑commerce brands may care more about attractive grain patterns for photos. Corporate gifts lean toward premium hardwoods with strong customization options. Qlychee Crafts can review your use case and suggest materials that match both function and budget.

Question 4: Can You Add Our Company Logo Or Custom Branding to the Trays?

Yes. Branding is one of the strengths of crafting wooden trays with CNC at Qlychee Crafts. We use laser engraving to apply sharp logos, text, and patterns in set zones on the tray. Vector formats such as SVG, AI, or high‑resolution PDFs work best, and our designers can help adjust artwork when needed.

For a richer effect, epoxy inlays can add color to your mark. Private‑label and gift‑ready packaging options extend that branding from the tray itself to the box, which raises perceived value for retail and corporate buyers.

Question 5: Are the Finishes Food‑Safe for Serving Trays Used in Restaurants?

For trays meant to touch food, Qlychee Crafts uses finishes based on food‑grade oils and waxes that meet common safety expectations for contact with snacks and drinks. These coatings soak into the wood, help block stains, and still allow easy re‑treatment by staff over time.

For non‑food trays, other clear coats and paints may apply instead. Our team can guide you toward the right finish based on your exact use and share details to support your own safety reviews and restaurant or hospitality clients.