There is immense satisfaction in creating something with your own hands. You know the importance of choosing the right materials for lasting results, especially for your DIY projects. The DIY home decor industry reached a massive $240.64 billion in 2021, showcasing the passion people have for these projects. The DIY craft and hobby market expects a 7.1% growth from 2025 to 2026, proving the lasting appeal of these projects.

Not all woods are equal for crafting quality drink coasters. This guide helps you identify the best wood for coasters in 2026. You must balance aesthetics, durability, and functionality for your wood projects. Consider moisture resistance, hardness, grain, and ease of working when selecting different woods for coasters. These factors ensure your woodworking projects, like these coasters, stand the test of time.

Key Takeaways

- Choose the right wood for your coasters. Consider its hardness, how it handles water, and its look.

- Seal your wooden coasters. This protects them from water and makes them last longer.

- Maintain your coasters. Clean them often and re-seal them when needed.

- Match the wood to your style. Think about your home decor and budget.

Selecting the Best Wood for Coasters

You need to choose the right wood for your DIY coasters. This section helps you understand key factors. Your choice impacts the look and life of your projects.

Coaster Wood Hardness and Durability

Hardness is crucial for coasters. You want wood that resists dents and scratches. Harder woods withstand daily use better. They retain their quality over time. Hardwoods like maple or oak are excellent choices. Softer woods, or softwoods, show wear quickly. Consider how much use your coasters will get.

Moisture Resistance and Stability

Coasters protect surfaces from moisture. The wood you pick must handle spills. Quarter-sawn lumber offers superior dimensional stability. This cutting pattern minimizes tangential movement.

For example, quarter-sawn oak has a dense grain structure, which improves its resistance to moisture. You want wood that resists warping or cracking. This ensures your coasters remain flat and functional.

Appearance and Grain Patterns

The wood’s visual qualities play a key role in your projects. Different woods showcase unique grain patterns and colors. You might prefer the light, uniform look of maple or the rich, dark tones of walnut. Certain woods, like cherry, change color over time as they age. Consider how the wood’s natural beauty fits with your style. Moreover, many types of wood can be stained or painted, offering additional design options for your coasters.

Workability and Finishing Potential

Think about how easy the wood is to work with. Some hardwoods are very dense. They require more effort to cut and sand. Softwoods are generally easier to shape. However, they might not offer the same durability.

You also need to consider finishing. Some woods take stain well. Others, like walnut, look great with just a clear coat. For laser cutting, maple, pine, cherry, and walnut are popular choices. They produce clean, precise designs.

Choosing a premium-quality wood ensures a better final product for your projects. This helps you create the best wood for coasters.

Best Wood for Coasters: Top 10 Woods for DIY Coasters

There are many great options when choosing wood for your DIY wooden coasters. Each type of wood has its own distinct qualities. Explore these popular woods commonly used for coasters to find the one that best suits your needs.

1. Maple Wood Coasters

Maple is a great versatile option for your coasters. It is a strong hardwood that withstands wear and damage well. You will appreciate its light color and fine grain. Maple stains and finishes well, giving you many design options. It is also good for laser cutting, allowing for intricate designs. However, you might find maple harder to work with hand tools due to its density.

2. Walnut Coasters

Walnut provides a sophisticated, deep dark color. This hardwood is highly durable and ideal for crafting stunning natural wood coasters. It works well with laser cutting, allowing for sharp, precise edges. The primary downside is its higher price compared to other woods, but its elegant look often makes the extra cost worthwhile for your projects.

3. Cherry Wood Coasters

Cherry wood features warm, rich tones and ages beautifully, gradually developing a deeper patina with time. You will find cherry good for laser cutting. Be aware that its color can darken significantly as it ages.

Cherry is among the ‘big four’ hardwoods, along with oak, maple, and walnut, making it an excellent option for your wooden coasters. It is a dense, premium hardwood known for its durability, smooth texture, and natural beauty. Cherry wood holds up well against moisture and wear.

While you can use various wood types for coasters, solid hardwood like cherry is recommended over plywood. Plywood can delaminate due to moisture from sweating drinks. Although moisture isn’t ideal for solid wood either, proper sealing prevents issues. You can easily fix minor damage by sanding and re-sealing. Cherry is a great wood for this project.

4. Oak Coasters

Oak offers classic strength and a prominent grain. It is an extremely durable hardwood. You will find oak excellent for heavy-use coasters. However, oak can be porous. This means you need good sealing to protect it from moisture. Its distinctive grain adds character to your projects.

5. Ash Coasters

Ash wood has a light color and is strong. It offers good flexibility and you might find ash less common for small projects like coasters. Ash wood, similar to oak, can be very hard. It has the potential to dull your tools quickly. Ash can also be prone to chipping, especially if the wood is very dry. The appearance of ash can be bland, suggesting you experiment with stains to enhance its look.

6. Birch Coasters

Birch is an economical wood with a fine grain that absorbs stain effectively. You can achieve various looks with birch. However, its grain is less distinctive than other hardwoods.

Kaitlyn W. notes a significant challenge with birch coasters: “Birch is super light when it’s dry and looks so good with fresh dark burning but as soon as the finish goes on it just makes it dark, murky, and blurry looking.” She specifically mentions issues with finishes like polycrylic causing the wood to “turn super dark and yellow.”

You should test finishes on a scrap piece of birch before applying them to your coasters.

7. Poplar Coasters

Poplar is easy to work with. It is good for painting or opaque finishes. You will find poplar a softer hardwood. This makes it less durable than other hardwoods on this list. It is a good choice if you plan to paint your coasters.

8. Cedar Coasters

Cedar is aromatic, and it offers natural pest resistance and a rustic look. You will find cedar a softer wood. This makes it prone to dents. Cedar is perfect for natural wood coasters if you appreciate its distinct scent and appearance.

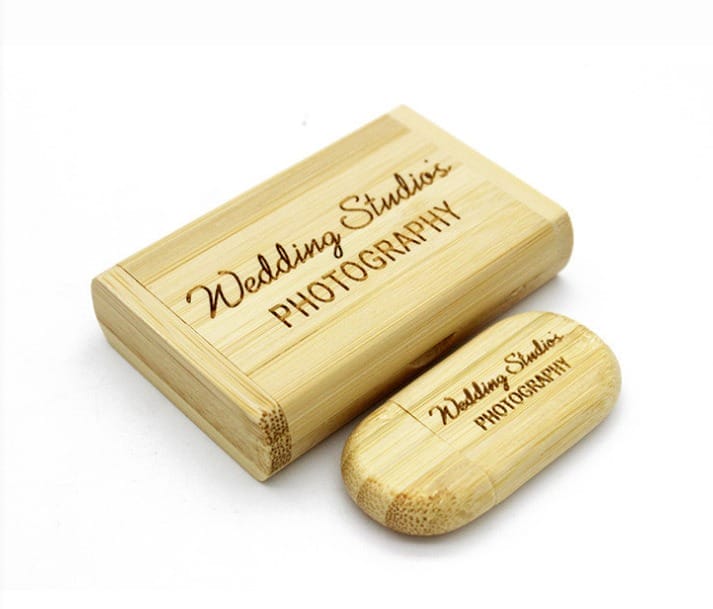

9. Bamboo Coasters

Bamboo is an eco-friendly material with a distinctive grain pattern, known for its strength and durability. You might find bamboo harder to cut cleanly. Bamboo possesses natural water-repellent properties. This contributes to its durability and suitability for coasters that will frequently host drinks. Bamboo wood has inherent properties, including porosity and grain structure. These make it more absorbent than many other wood types, allowing it to trap and hold moisture effectively.

However, bamboo also presents challenges:

- Low Water Absorption: Bamboo has low porosity. Untreated bamboo coasters absorb only a small percentage of their dry weight in 30 seconds. They shed excess moisture laterally once saturated, increasing the risk of seepage.

- Poor Thermal Insulation: Bamboo has moderate heat conductivity and is less effective at insulating against cold shock compared to cellular materials. Additionally, it may discolor or emit odors when exposed to temperatures above 80°C.

- Coating Issues: Many commercial bamboo coasters are coated with acrylic or melamine. These coatings can develop micro-scratches over time, which weakens the seal. Additionally, repeated exposure to temperature changes may cause some coatings to release formaldehyde.

- Durability and Aesthetic Degradation: After 180 days, bamboo coasters showed issues like faint white halos from shifting. You might also see visible micro-scratches from cutlery. Slight darkening can occur where condensation penetrates surface imperfections. They also require replacement after 2 years or at the first sign of coating failure.

- Aesthetic Drawbacks: Bamboo’s high-gloss finish reflects light, making it stand out and potentially clash with other items. Its rigid, geometric shape can also look unnatural when placed alongside handcrafted pieces.

- Maintenance and Vigilance: Bamboo coasters need careful placement and regular checking. You should be aware of trade-offs such as lower absorption and weaker insulation. Their smooth surface also demands intentional repositioning to keep them properly aligned.

10. Red Heart Coasters

Red Heart wood features a striking, vivid red color, giving your coasters a unique and bold look. It tends to be more expensive, and its bright color can fade over time when exposed to UV light. Despite this, it produces truly attention-grabbing pieces.

The Best Wood Types for Coasters – Factory Perspective

When you consider making coasters on a larger scale, a factory perspective introduces new considerations. You must balance material properties with production efficiency and cost.

Selecting Species Suitable for Mass Production

For mass production, you need wood species that offer consistency. Factories look for uniform density and minimal defects. This ensures smooth processing through machinery. Wood that cuts cleanly and sands easily reduces production time. Maple and birch are often favored for their consistent grain and workability. These woods allow for predictable outcomes when creating many identical coasters.

Availability and Costs of Commonly Used Woods

Cost and availability significantly influence factory choices. You want materials that are readily accessible and budget-friendly.

| Material Type | Cost Index |

|---|---|

| Cork | Low-Medium |

| Bamboo | Low |

Economic analysis shows that premium materials, despite higher initial costs, can offer a better return. Their extended lifespan means fewer replacements. For commercial uses, cork and bamboo are excellent choices for coasters. They have an expected lifespan of 2-5 years. Their annual cost ranges from $0.50 to $1.25, providing good value for the performance.

- Hardwood: Hardwood is pricier than softwood and demands higher laser power along with slower cutting speeds, which raises production time and costs. Despite this, hardwood is perfect for creating durable, premium coasters that can endure wear and tear.

- Plywood: Plywood provides an affordable and versatile choice. It has consistent thickness and resists warping from heat, allowing for accurate cuts on your coasters. It’s important to select high-quality, void-free plywood to prevent problems caused by glue gaps and knots.

Impact of Mechanical Characteristics on Production and Durability

The mechanical properties of wood have a direct impact on both production and the durability of the finished product. Harder woods, such as oak or maple, resist dents and scratches well, making them ideal for durable, long-lasting coasters. However, their hardness can cause cutting tools to wear out more quickly, leading to higher maintenance costs. Softer woods are easier to cut but may not provide the same level of durability for your coasters.

Moisture resistance is also key. Wood that resists warping or cracking ensures your coasters remain functional and attractive. You must choose wood that can withstand repeated use and exposure to liquids.

Finishing Your DIY Wooden Coasters

You put effort into making your coasters. Now, you must protect them. The best finish for wood coasters ensures your creations last.

Why Coaster Sealing Is Crucial?

Sealing your coasters is very important. It protects them from moisture. This prevents warping, cracking, and rotting of the wood. Sealed coasters also look better. They show a richer color and a glossy finish. This highlights the wood’s natural grain.

You will find them easier to clean. They absorb fewer liquids and stains. Sealing increases their durability. It guards against damage from heat, moisture, and spills. This extends their lifespan. Sealing also stops mold and bacteria growth. This makes your coasters safer for home use.

Best Sealants and Finishes

You have several options for sealing your coasters. Waxes offer a natural finish. Carnauba wax is plant-based and very durable. Candelilla wax is another plant-based choice. Soy wax provides some protection. Food-grade paraffin wax is also available. You can even use coconut oil with olive oil for a plant-based option. For stronger protection, consider polyurethane or epoxy. These create a hard, protective layer on your DIY wooden coasters.

| Sealant/Finish | Type & Protection | Durability & Use | Appearance & Notes |

|---|---|---|---|

| Carnauba Wax | Plant-based, Medium | Good; home decor, wood items | Smooth, natural; durable, eco-friendly |

| Candelilla Wax | Plant-based, Medium | Good; wood crafts | Semi-transparent; harder than soy wax |

| Soy Wax | Plant-based, Low | Fair; light protection | Soft matte; water sensitive |

| Food-grade Paraffin Wax | Petroleum-based, Medium | Medium; food surfaces | Smooth shine; food safe, affordable |

| Coconut + Olive Oil Mix | Plant-based oils, Low | Fair; light protection | Natural matte; not water resistant |

| Polyurethane | Synthetic, High | Very good; furniture, floors | Hard gloss/matte; durable, water resistant |

| Epoxy Resin | Synthetic, Very high | Excellent; heavy-duty use | High gloss, thick; hardest protection |

Application Tips for Longevity

Applying sealant correctly ensures long-lasting results.

- First, clean your wooden coasters. Make sure they are free of dust or dirt.

- Next, sand the surface. Use fine-grit sandpaper to smooth any rough spots.

- Then, apply the sealant. Use a brush or roller. Follow the manufacturer’s instructions carefully.

- Let the sealant dry completely. For more protection, apply a second coat after the first dries.

If you use polyurethane, wait at least 24–48 hours for light use. Full curing takes longer. Water-based types need 7–21 days. Oil-based types need about 30 days for maximum water resistance. Spraying polyurethane can work, but it needs practice. Ensure good lighting and warm temperatures to avoid issues.

Maintaining Your Wood Coasters

You can keep your coasters looking great for years. Seal them regularly. Wipe them with a damp cloth to remove dirt. Clean up spills immediately. This stops liquids from soaking into the wood. Avoid extreme temperatures. Keep your coasters away from direct heat or cold. This prevents warping or cracking. Always use protective layers. Place your coasters under glasses. This prevents water rings and damage.

DIY Steps for Wooden Coasters

Making your own wooden coasters is straightforward. Follow these steps for the best results:

- Choose Your Wood

Select wood that fits your style and needs, considering hardness, grain, and color. - Gather Tools and Materials

Prepare necessary tools such as a saw, sandpaper, clamps, and a laser cutter if available. - Cut the Wood

Cut the wood into coaster-sized pieces, typically squares or circles about 3.5 to 4 inches (9–10 cm) wide. - Sand the Edges and Surface

Smooth all surfaces and edges using progressively finer sandpaper for a clean finish. - Apply Design (Optional)

Use laser engraving, wood burning, or painting to add patterns or personalization. - Seal the Coasters

Apply a suitable sealant like polyurethane, wax, or epoxy to protect from moisture and wear. - Let Dry and Cure

Allow ample drying and curing time according to the sealant’s instructions before use. - Maintain Regularly

Clean your coasters gently and reseal periodically to keep them in good condition.

Following these steps will help you create durable and attractive wooden coasters that showcase your craftsmanship.

Choosing the Right Type of Wood for Your DIY Wood Coasters

You have explored many wood types. Now, make your final selection. This section guides you in choosing the best wood for coasters based on your needs. Your personal preferences and project goals are important. You will find the best wood for coasters that fits your vision.

Matching Wood to Your Style

Your personal style guides your choice for wood projects. Do you prefer a modern look? Maple or birch offer clean lines. Do you like rustic charm? Cedar or oak fit well. Consider the existing decor in your home. You want your DIY projects to complement your space. Think about the colors and textures you enjoy. This helps you pick the perfect wood for your coasters.

Budget-Friendly Coaster Options

Cost is a factor for many projects. You can create beautiful coasters without spending a lot. Pine and poplar are affordable choices. They are easy to work with. These woods are great for DIY projects. You can stain or paint them to match any style. Bamboo is another cost-effective option. It offers sustainability. These budget-friendly options allow you to make many coasters.

Sourcing Sustainable Wood

You can make eco-conscious choices for your wood projects. Look for sustainably harvested wood. Certified wood ensures responsible forestry practices. Bamboo is a highly renewable resource. Reclaimed wood is another excellent option. It gives old materials new life. Choosing sustainable wood helps the environment. Your woodworking projects can be both beautiful and responsible. These wood projects contribute to a healthier planet.

Tools and Techniques for Coaster Making

You need basic tools for your coaster projects. A saw, sandpaper, and clamps are essential. A router can add decorative edges. For laser cutting, ensure your wood is suitable. Maple, cherry, and walnut work well. Practice your techniques on scrap wood first. This builds your confidence. You will create high-quality coasters with the right tools and practice.

Suitable Woods for Different Uses

When selecting wood for your coasters, consider the specific conditions and purposes they will serve.

Outdoor Use

For outdoor coasters, moisture resistance and durability are key. Woods like teak, cedar, and bamboo naturally repel water and resist decay. Proper sealing is essential to protect them from weather exposure.

Best Woods for Laser Cutting

If you plan to use laser cutting, choose woods that cut cleanly without excessive burning or charring. Maple, cherry, walnut, and pine are excellent choices. Their consistent grain and density help produce sharp, precise designs.

Budget-Friendly DIY Options

If you’re working within a budget, consider affordable woods like pine, poplar, or birch. These woods are easier to work with and can be stained or painted to achieve different looks. Bamboo is also cost-effective and sustainable but may require more care in finishing.

By matching the wood type to your project’s environment and goals, you can ensure your wooden coasters will look great and last longer.

Final Words

You now understand the importance of thoughtful wood selection for your DIY coasters. You learned about crucial factors like hardness, moisture resistance, and aesthetic appeal. Experiment with different wood types to match your project goals and personal preferences.

- Choose wisely: select wood that fits your needs.

- Create uniquely: design coasters that reflect your style.

- Share proudly: show off your woodworking skills.

Embark on your next woodworking adventure today. Share your DIY coaster creations with the world!

FAQ

Can I use softwood for my DIY coasters?

You can use softwood, but it is less durable. Softwoods like pine dent and scratch easily. They do not withstand heavy use as well as hardwoods. You should choose hardwoods for long-lasting coasters.

What is the best way to protect my wooden coasters from water rings?

You must seal your wooden coasters properly. Use a waterproof sealant like polyurethane or epoxy. This creates a barrier against moisture. Always wipe up spills quickly. This prevents water from soaking into the wood.

Are there good non-wood alternatives for making coasters?

Yes, you have several options. Materials like silicone, ceramic, and even cork make excellent coasters. Cork is naturally absorbent and lightweight. You can also find coasters made from stone or fabric. Each material offers different aesthetics and protective qualities.

How often should I re-seal my wooden coasters?

You should re-seal your wooden coasters every 6 to 12 months. This depends on how often you use them. If you notice water soaking into the wood, it is time to re-seal. Regular maintenance keeps your coasters looking new.