Picture a breakfast tray sliding onto a hotel bed or a row of candles arranged on a clean wood board in a product photo. Behind that simple moment sits a very specific craft: crafting wooden router trays so they are safe, stable, and good-looking every single time. When the routing, sanding, and finishing are right, the tray disappears and the experience shines.

For wholesale buyers and retailers, wooden tray making is far more than a weekend project. Router-made trays become serving trays, display pieces, organizers, and gift packaging that help brands sell more. Hand tools and a plunge router can shape a beautiful one-off piece, but once you need hundreds of the same tray, the picture changes. Safety rules, sustainable sourcing, and repeatable quality suddenly matter as much as style and grain.

This guide walks through both sides. You see how woodworking tray projects work at the bench level and why DIY production struggles at scale. Then you see how Qlychee Crafts uses CNC routing, laser engraving, eco-friendly finishes, and smart wholesale terms to solve those pain points. By the end, you know what makes a professional tray, how to judge suppliers, and how Qlychee Crafts can help you put safe, sustainable, handmade wooden trays in front of your customers with confidence.

Key Takeaways

- Crafting wooden router trays starts with good material and smart planning. You need flat stock, safe wood router techniques, accurate templates, and a staged routing plan that covers bulk removal, cavity shaping, edge profiling, sanding, and food-safe finishing. These steps protect both the end user and your brand reputation.

- Traditional DIY wooden trays work well for a hobby shop but are risky for business-scale orders. Hand routing often leads to depth changes, template slips, long sanding time, and shop safety concerns, which makes a two-to-four-hour tray hard to use as a wholesale item. CNC-based production removes most human error while still allowing custom wooden trays.

- Buyers now expect sustainable woodworking and safe finishes. Fast-growing bamboo and documented hardwoods fit green policies, while low-VOC, food-safe oils and waxes are required for serving tray use. That combination supports restaurant compliance and gives retailers a clear marketing story.

- Qlychee Crafts brings all of this together for you. The factory uses CNC routers, laser engraving, and automated spray finishing, offers low MOQ and dropshipping support, and often costs less than setting up a full router table, jig collection, and finishing line on your own. You gain consistent product quality and a partner focused on eco-conscious, safe production.

Understanding Wooden Router Trays: Applications and Market Demand

Wooden router trays are shallow wooden vessels with a routed interior pocket and a flat bottom, somewhere between a cutting board and a bowl. The router base follows a template to carve a clean cavity, then edge bits shape the perimeter. This makes trays that are lighter than solid boards but more stable and practical than deep bowls.

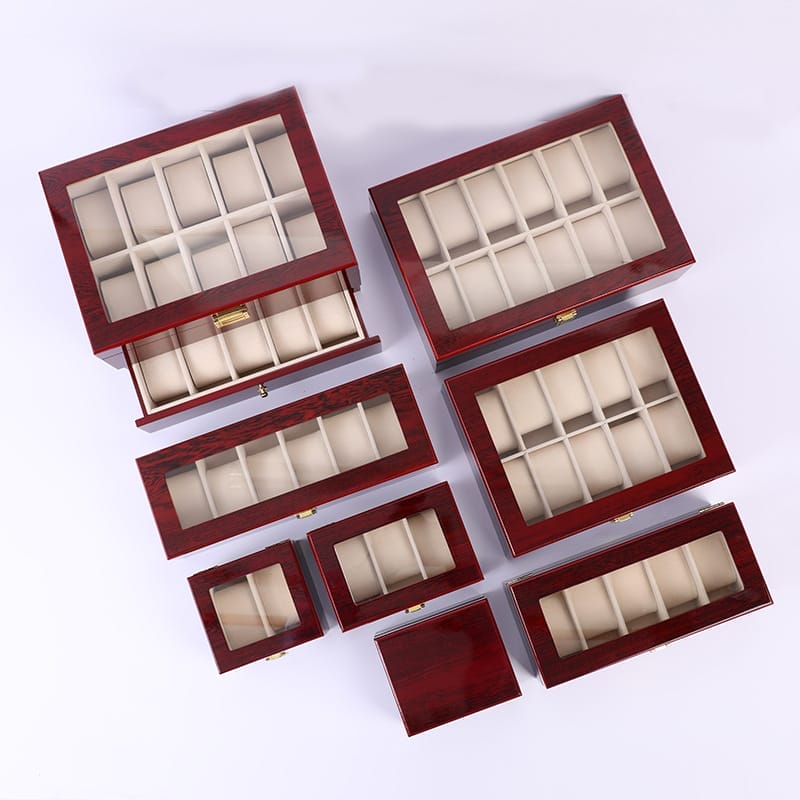

Because you can change the template, you get endless wood tray designs. Rectangular serving trays, oval catch-alls, slim desk organizers, and multi-compartment snack trays all come from the same core process. That flexibility explains why these pieces are growing in hospitality, retail, e-commerce, and corporate gifting.

Hospitality Sector

In hospitality, crafting wooden router trays creates serving pieces that look warm and natural yet stand up to daily use. Restaurants use them for bread, sliders, and shared plates, while hotels rely on them for room-service breakfast and minibar setups. Food-safe finishes and reliable thickness keep trays stable under plates and cups, which avoids spills and complaints.

Retail Merchandising

Retailers use routed trays as quiet stage pieces. Jewelry sits inside a shallow pocket so it does not slide, and stationery looks tidy on a wooden desk tray. Consistent shapes, smooth routed edges, and neat finishes help products look higher grade, which supports better margins for you.

E-Commerce

Online brands love DIY wooden trays as props for flat lays and unboxing videos. A clean acacia tray under candles, spa kits, or tech accessories makes product photos more shareable without stealing focus. When you repeat the same tray across listings, customers start to link that style with your brand.

Corporate Gifting

For corporate gifts, routed trays act as both packaging and long-term decor. A company logo, engraved on the rim or center, stays in view long after snacks or welcome items are gone. With laser engraving and consistent tray scale, Qlychee Crafts helps you ship branded sets that feel thoughtful without needing you to manage workshop gear.

Essential Materials: Wood Selection for Professional Tray Making

The wood you choose sets the tone for the whole product. It affects how smooth the routed bowl area feels, how well finishes bond, and how the tray handles moisture in kitchens or bathrooms. For wooden tray making at a commercial level, hardwoods are usually better than softwoods because they resist dents and give a finer surface for sanding.

Premium hardwoods bring different looks and price points. Acacia, a Qlychee Crafts specialty, has strong grain lines, natural water resistance, and great durability, which suits busy restaurants. Walnut reads as dark and high end, maple as light and modern, cherry as warm and classic, and mahogany as rich and easy to machine.

You also have sustainable choices. Bamboo grows in three to five years instead of decades and is popular with eco-focused shoppers. Qlychee Crafts can share documentation on bamboo and hardwood origins, which helps when you work with green procurement rules. For display-only use, MDF and plywood can work as tray cores, especially when combined with quality veneers and edge-banding.

A quick overview can help you compare options.

| Material | Look and Style | Typical Use | Notes |

|---|---|---|---|

| Acacia | Strong grain, medium tone | Serving tray, seed tray | Durable, moisture friendly |

| Walnut | Dark and rich | Luxury retail, gifts | Commands higher pricing |

| Maple | Pale and clean | Minimalist brands | Very smooth grain |

| Cherry | Warm red-brown | Classic home decor | Deepens over time |

| Bamboo | Light, linear grain | Eco-focused lines | Fast-renewing choice |

For most woodworking router projects, tray stock between 7/8 inch and 1 1/4 inch gives enough thickness to rout a safe cavity while keeping weight under control. Material cost feeds into your MOQ and price strategy, so choosing the right species and thickness helps you balance margin with market expectations.

DIY Router Tray Crafting: Traditional Techniques and Limitations

At the bench level, crafting wooden router trays follows a clear pattern. You make a template, mount it to the blank, remove bulk waste with a drill press or router, shape the cavity with a bowl bit, then trim and profile the outside.

Many woodworkers share router template guide ideas and router jig plans on forums and love this process. For a business, though, it has limits.

1. Template Creation Fundamentals

You often build templates from MDF or clear acrylic, or buy commercial ones when speed matters. Simple shapes come from printed drawings or basic design software, then get cut with a jigsaw and cleaned up by hand. The more accurate this template is, the easier every tray after that becomes.

2. Router Setup Essentials

For safe wood router techniques, a guide bushing kit in the router base keeps the cutting bit away from the template edge. You must account for the offset between bushing and cutting diameter so the cavity ends up the right size. Many makers also swap to a larger, clear base plate for better control and visibility.

3. Material Removal Stages

DIY woodworking tray projects remove wood in phases so the router bit does not overheat. You plan where to drill, where to rout, and how deep each pass goes. This staged approach keeps the cut smooth and easier to sand.

4. Bulk Removal (“Hogging”)

Most makers start with a drill press and a wide Forstner bit. Overlapping holes inside the traced tray shape remove most of the core material very fast. This means the router has less work to do and stays cooler.

5. Primary Routing

After hogging, you switch to a bowl and tray router bit. Short, shallow passes slowly flatten the bottom and soften the corner radius. Moving the router in a steady pattern helps avoid gouges and makes sanding easier.

6. Perimeter Cutting

To match the outer edge to the template, you use a flush trim bit with a bearing. The bearing rides the template, and the cutter trims the perimeter clean. Many woodworkers rough cut on a bandsaw first so the bit has less to remove.

7. Edge Profiling

A roundover bit softens the rim for a comfortable grip, while a chamfer bit creates a crisp, modern angle. Both run either in a router table or with a handheld fixed base router. Correct feed direction and a sharp cutter keep edges from burning.

8. Critical Safety Considerations

Router work demands strong shop safety habits:

- Clamp the tray blank firmly so it cannot twist under the bit.

- Keep eye, ear, and dust protection on at all times.

- Use dust collection or a shop vacuum to catch fine particles before they reach your lungs.

Skipping any of these basics increases the odds of kickback, chipped parts, or long-term health issues.

9. Inherent DIY Limitations

For fun projects, these steps feel satisfying. For wholesale runs, you start to see weak points. Even with practice, little changes in hand pressure or feed speed create inconsistencies.

Inconsistency Issues: Depth Variations, Uneven Feed Rates, Misaligned Templates

A small slip in template alignment can shift the whole tray shape. Uneven pressure on a plunge base changes cavity depth, which makes stacks of trays look off. These flaws are hard to fix once the bit has cut.

Time Investment: 2–4 Hours Per Tray Unsuitable for Wholesale Volume

Even a skilled enthusiast often spends a couple of hours on one tray when you include sanding and finish. That pace does not match a shop that needs hundreds of units ready for a season. Time also adds to your real cost per piece.

Quality Variability: Human Error, Fatigue Affecting Precision

As fatigue sets in, hands shake, and mistakes increase. A missed stop line with a bowl bit or a wrong pass on the router table can scrap a nearly finished tray. That risk grows with bigger orders.

Scalability Problems: Cannot Meet Large Orders or Retailer Timelines

If a retailer asks you for 1,000 routed trays, a hand process cannot keep up without more people and more routers. Deadlines for launches or holiday sets become stressful or impossible. Late orders can strain buyer relationships.

Initial Investment: Router Table, Multiple Bits, Jigs, Safety Equipment Costs

Many people think DIY saves money. In practice, you buy a quality router, router table accessories, a plunge base, several router bits for trays, jigs, a drill press, clamps, and safety gear. Once you add that up, outsourcing to a shop like Qlychee Crafts often looks more attractive.

Professional Manufacturing Approach: Qlychee Crafts’ Automated Process

For wholesale buyers, consistency and speed matter as much as style. This is where crafting wooden router trays with automated tools beats a home shop. Qlychee Crafts uses CNC routers, laser machines, and controlled finishing lines to give you the look of handmade wooden trays with the predictability of factory work.

1. CNC Routing Advantages

CNC routing holds tolerances near 0.1 millimeter, far tighter than hand routing can maintain. It repeats the same oval or rectangular template path thousands of times without drifting. Complex curves, inlays, and multi-compartment layouts that are painful by hand become standard options.

2. Integrated Production Workflow

Your drawings, mood boards, or even simple sketches become digital tray models. Software nests these shapes on boards or bamboo panels to reduce scrap and optimize yield. The same file then guides the CNC, which replaces the manual jig, plunge router, and drill press steps.

3. Laser Engraving Integration

Laser engraving adds logos, text, or patterns without building new physical jigs. Position and depth sit in software, so moving a logo from the corner to the handle area is a simple change. This makes branded router table accessories like bar trays or menu boards easy to update.

4. Precision Edge-Banding

When you choose MDF or plywood cores, Qlychee Crafts uses precision edge-banding machines. These wrap clean strips around exposed edges, so the tray looks like solid wood. The result is a smooth perimeter with no rough layers showing.

5. Automated Spray Finishing

Robot-guided or track-based spray systems apply the same coating thickness to every tray. This cuts down on runs, dry spots, and uneven sheen. Controlled drying rooms then cure finishes quickly without dust settling on the surface.

6. Quality Control Checkpoints

Material enters the line only after moisture checks and grain inspections. During routing, samples are pulled to confirm tray depth, shape, and wall thickness. Before packing, staff inspect the surface by eye and touch so any sanding marks or finish issues are caught.

7. Customization Without Compromise

Because everything starts in digital form, changing tray size or compartment layout does not require new steel tools. You can adjust depth, radius corners, or even add smartphone slots in a serving tray. Multi-wood combinations and inlay bands are also easy to repeat in large numbers.

8. Sustainability in Manufacturing

Central dust collection captures shavings and sends them for reuse or energy generation instead of landfill. Machines use energy-efficient motors and smart scheduling to reduce idle time. Water-based, low-VOC coatings keep air cleaner for staff and for your end customers.

9. Wholesale Buyer Benefits

You receive trays that match your drawings, batch after batch, without guessing which pieces are good enough for product photography. New designs move from idea to sample and then to a full run with clear timing. You also skip the learning curve, tool wear, and safety risks of running a router shop yourself.

Surface Finishing and Treatment: Achieving Premium Quality

Routing only shapes the wood. What shoppers and restaurant staff feel is the finish. A smart sanding schedule, thoughtful coating choice, and clean buffing step take wooden router trays from rough blanks to retail-ready showpieces that slide smoothly in the hand.

Sanding Progression Fundamentals

Most trays move through sanding grits from 80 to 120, then 180 and 220. Coarse grits remove router lines and bearing marks, while finer grits polish the curves. Many makers also raise the grain with a light water mist, then do a final sand for extra smoothness.

Food-Safe Finishing Options Critical for Serving Trays

When the tray touches food, finish choices matter as much as wood species. You want coatings that do not add smell or chemical taste, which is why food-safe oils and waxes are so popular.

| Finish | Food‑safe? | Odor | Water resistance | Durability | Maintenance |

|---|---|---|---|---|---|

| Mineral oil (food‑grade) | Yes | None | Low | Low | Reapply every few weeks–months |

| Beeswax + mineral oil | Yes | Very low | Low–Medium | Low–Medium | Reapply every few months |

| Polymerized natural oils (tung/boiled linseed, food‑safe) | Often (check label) | Low after cure | Medium | Medium | Recoat infrequently — months to years (follow cure instructions) |

Mineral Oil

Plain mineral oil soaks into the wood and protects from within. It gives a natural, low-sheen look that many restaurants like. The tradeoff is that it needs refreshing as the tray gets washed and wiped over time.

Beeswax and Mineral Oil Blends

Blends that mix mineral oil and beeswax add a light sealing layer on top of the wood. The wax helps water bead instead of soaking in, while the oil still feeds the fibers. These blends give a soft glow that photographs well.

Polymerized Natural Oils (Tung, Linseed)

Polymerized oils cure into a tougher film than straight mineral oil. They offer better scratch resistance, which pays off in busy bars and cafes. Cure time matters, so production schedules need room for these coats to harden.

Decorative Finish Options for Non-Food Applications

For desk trays, vanity organizers, and display pieces, you can consider water-based polyurethane, gentle stains, or lacquer. These highlight the grain and add protection against cosmetics, pens, or jewelry. High-gloss lacquer, in particular, creates a glass-like look that suits gift lines.

Finishing Process Stages

Before any coat goes on, dust must leave the surface, including corners and inlay lines. Sprayed finishes work best for large runs, while hand-rubbed oils suit small batches and special orders. Cure time shapes shipping dates, so wholesale plans must allow for that window.

Quality Indicators for Wholesale Buyers

When samples arrive, run your fingers along curves and handles. A good tray feels even, without sharp spots or sanding swirls. Water should bead gently, and there should be little to no lingering finish smell.

Packaging Considerations

Freshly finished trays rub against each other in transit when packaging is weak. Qlychee Crafts uses paper wrap, corner guards, and recyclable fillers to shield edges and faces. This keeps surfaces smooth and reduces returns from scuffs or dents.

Safety and Sustainability: Meeting Modern Standards

Modern buyers care about how things are made, not just how they look. When you choose a partner for crafting wooden router trays, you are also choosing how workers are treated and how forests are managed. That story shows up in marketing copy, audits, and, in many cases, purchase approvals.

“Sustainable development is development that meets the needs of the present without compromising the ability of future generations to meet their own needs.” — Gro Harlem Brundtland

Safety in DIY Router Operations

Hand routing brings real risk when basic rules slip. Kickback happens when a bit grabs too much wood or the workpiece is not clamped, which can throw the tray or tool. Fine dust from MDF or hardwoods stresses lungs without proper masks and extraction.

Professional Manufacturing Safety Advantages

In a factory like Qlychee Crafts, CNC machines keep cutting tools inside guarded areas. Operators load blanks and remove finished parts instead of holding them near a spinning cutter. Automated dust extraction and regular maintenance programs lower accident rates and create a cleaner workplace.

Sustainable Material Sourcing

Sourcing logs and panels from legal operations protects both forests and your brand. Buyers in larger groups often ask for documents that show where wood comes from. Qlychee Crafts maintains this paper trail and can share it when you need it for compliance teams.

Bamboo Certification: FSC-Equivalent Fast-Growth Verification

Bamboo trays help you move toward lower-impact assortments. Certification systems similar to FSC confirm that the bamboo comes from responsibly managed sources and that regrowth cycles are honored. This gives you a clear claim in catalogs and product pages.

Eco-Friendly Production Practices

Finishing lines at Qlychee Crafts focus on water-based and low-emission coatings. Waste wood from routing becomes either secondary products or fuel instead of trash. Minimal plastic in packaging also speaks directly to eco-minded shoppers.

Certifications and Compliance

Food-contact trays rely on finishes that meet FDA and similar European standards. Environmental systems can align with ISO 14001 style frameworks, which matter to larger retailers. Product safety tests cover issues like finish adhesion and structural strength.

Marketing Value for Retailers

When you can show clear safety and sustainability practices, you gain more than peace of mind. Product pages tell a better story, and staff can explain why your trays cost more than plastic. This helps support higher price points and brand loyalty.

Customization Options: Aligning Trays With Your Brand

Style details turn a simple tray into a brand asset. With crafting wooden router trays at scale, you can set size, shape, compartments, engraving, and finish so the piece fits your look. Qlychee Crafts treats these options as normal parts of the process, not rare favors.

Dimensional Customization

You choose tray length, width, and height. Standard sizes suit common tables and counters. Custom sizing fits special shelves or packaging. Thickness also shifts from slim display boards to heavier serving pieces.

Shape Variations

Rectangular forms with rounded corners feel familiar and stack well. Ovals and circles read softer and fit centerpieces. Organic curves look artistic on coffee tables. Nested sets let you sell bundles with rising sizes.

Compartmentalization Options

Some trays hold one large pocket for bread or towels. Others divide into wells for sauces, snacks, or office items. Qlychee Crafts can rout utensil slots and special insets so every tool has a home.

Branding and Personalization

Branding turns any tray into a long-lived sign. You can add a subtle mark in a corner or make the logo the main graphic. Names, dates, or short quotes also work well for gift programs.

Laser Engraving: Logos, Text, Decorative Patterns With Precision Detail

Laser beams carve clean lines into the surface with high accuracy. Fine text, thin lines, and repeat patterns appear the same on every piece. This keeps your identity sharp even on small trays.

Depth and Size Specifications for Engraving

Engraving depth can stay shallow for smooth cleaning or go deeper for stronger contrast. Sizing matches your logo guidelines so shapes look correct. Qlychee Crafts tests settings on scrap first before running full batches.

Wood Combinations and Inlays

You can pair light maple with dark walnut bands or add thin inlay strips along the edge. These touches make trays feel more special without changing basic function. Mixed woods also help collections stand out online.

Finish Customization

Stain colors can echo your brand palette, from cool grays to warm browns. Matte or satin sheens fit casual looks, while gloss suits luxury sets. Two-tone effects, with one look inside and another outside, add more design range.

MOQ Flexibility: Small Sample Runs for Testing Before Large Orders

You may want to test a style before going all in. Qlychee Crafts offers small sample batches so you can photograph, list, and sell before scaling up. Once demand is clear, production ramps without changing the process.

Wholesale Partnership Benefits: Working With Qlychee Crafts

Choosing a tray supplier is a long-term business decision. You need more than good-looking photos; you need reliable lead times, fair terms, and support as your product line grows. Qlychee Crafts is set up to serve that role for wooden router trays at scale.

1. Flexible Minimum Order Quantities

Starting a new tray line should not require warehouse-level commitments. Typical minimums fall in the 100 to 500 unit range, depending on complexity. Smaller test runs help you confirm fit with your audience before moving to larger brackets with better pricing.

2. OEM/ODM Service Capabilities

If you have only a rough sketch, Qlychee Crafts can turn it into a production-ready design. Samples usually arrive within one to two weeks for review. Feedback cycles refine radius corners, handle shapes, and engraving placement until they match your needs.

3. Production Efficiency Advantages

Clear production schedules explain when routing, finishing, and packing happen. Capacity scales from test runs around 100 units up to orders over 10,000 when a tray takes off. Rush options exist for seasonal peaks when timing is tight.

4. Logistics and Shipping Support

A good product means little if it arrives damaged or late. Qlychee Crafts optimizes inner packaging and control cartons to handle sea freight, air freight, or express services. Dropshipping options also support e-commerce brands that ship straight to customers.

5. Quality Assurance and Returns

Before shipping, teams inspect dimensions, grain, sanding quality, and engraving clarity. You receive photo or video reports so you can sign off with confidence. Clear defect rules and replacement terms protect your business if issues appear.

6. After-Sales Support

Once your first order lands, support does not end. You can adjust designs for next runs, explore new wood species, or plan related woodworking router projects. Feedback loops help keep your tray line fresh and aligned with trends.

7. Competitive Pricing

Because Qlychee Crafts is a direct manufacturer, you do not pay extra layers of markup. Transparent pricing shows how wood, machining, finishing, and packing contribute to the final cost. This helps you plan retail margins and compare value with other suppliers.

Conclusion

Crafting wooden router trays combines woodworking skill with smart business planning. Learning how templates, router bits, sanding, and finishing work will help you judge samples and understand what you are buying. Seeing the limits of DIY routing also makes it clear why commercial buyers move toward automated production instead of building their own router table setups.

Across hospitality, retail, e-commerce, and corporate gifting, routed trays pull weight as serving pieces, display props, organizers, and branded gifts. They carry food one day and star in lifestyle photos the next. When they are made from good wood, routed cleanly, and finished with safe, eco-minded coatings, they quietly upgrade every scene they enter.

Qlychee Crafts stands at the point where precision automation meets design freedom and sustainability. You get consistent tray quality at scale, low MOQs and flexible terms, traceable materials, and a deep menu of customization options. That mix offers a clear edge over DIY production or suppliers who cannot show how they handle safety and green practices.

If you are ready to expand your wooden tray line, now is the time to act. Reach out to Qlychee Crafts for custom samples, design feedback, and clear quotes. Explore existing wooden serving tray plans and material options, then build a collection that your customers will use and remember for years.

FAQs

What Is the Minimum Order Quantity for Custom Wooden Router Trays?

For most custom trays, Qlychee Crafts works with minimum order quantities in the 100 to 500 unit range, depending on design complexity and material.

You can also start with very small sample runs of around 5 to 10 units for product testing. Volume discounts begin as quantities rise into the hundreds and thousands, which supports strong retail margins.

Compared with many factories, these minimums are relatively low, making it easier for you to launch new styles.

How Long Does Production Take from Order to Delivery?

Standard production time for crafting wooden router trays at Qlychee Crafts is about 20 to 30 days after sample approval. Samples themselves usually take 7 to 10 days so you can test size, finish, and engraving. Lead time depends on order size, customization, and seasonal demand, so clear planning helps.

For urgent projects, expedited runs can bring production down to roughly 15 days, with an added rush fee. Shipping then adds around 30 to 45 days by sea or 5 to 7 days by air.

Are Your Wooden Trays Food-Safe and Suitable for Restaurant Use?

Yes, Qlychee Crafts designs serving trays with restaurant use in mind. Hardwoods and bamboo suited to food-contact work combine with finishes like mineral oil and certified wood wax oils that meet FDA-style expectations. Low-VOC systems keep odors and chemical migration very low, which matters on busy tables.

Each tray ships with basic care guidance so staff know how to clean and recondition the surface. Test reports and finish documents are available if your chain or distributor requires proof.

Can You Match My Brand’s Specific Wood Color or Finish?

In many cases, Qlychee Crafts can get very close to your target color and sheen. Stain mixing and sample panels help match physical swatches or printed brand guides. Choosing a wood species with a similar base tone also supports the match.

You can specify matte, satin, or gloss looks, and approve a sample before a full run. Natural wood always has some variation, and this is explained clearly during consultation so expectations stay realistic.

What Customization Options Are Available for Branding?

Branding can appear in many ways on handmade wooden trays produced at scale. Precision laser engraving handles logos, taglines, and patterns with fine detail on handles, corners, or tray bottoms. Engraving depth and size change the look from subtle tone-on-tone to strong contrast.

You can also add branded packaging such as labels, hang tags, and inserts for retail shelves or online orders. For best engraving results, Qlychee Crafts works with vector design files and offers design advice on placement and scale.

How Do You Ensure Consistent Quality Across Large Orders?

Quality starts with automated CNC routing, which keeps every cavity shape, wall thickness, and radius within tight tolerances. Qlychee Crafts groups wood from the same lot to reduce strong color shifts inside a batch.

Multi-stage inspections check dimensions, sanding, engraving, and finish before trays move to packing. First article samples from a run let you confirm details before full output continues. If any pieces miss the agreed standard, clear replacement and claim rules protect your orders.